-

Home >> Solutions >> Design and diagram

1000 TPD SSP/TSP Phosphate Fertilizer Plant in Indonesia

Meta Description: Explore how our 1000 tons/day SSP/TSP phosphate production line boosted a client's fertilizer output. This case study covers this high-capacity phosphate fertilizer plant's efficiency, ROI, and why Gofine Machine is a leading fertilizer equipment manufacturer.

Scaling Up Production: A 1000 TPD SSP/TSP Line Success Story

For global fertilizer equipment manufacturers, the challenge isn't just building machines; it's about delivering scalable, profitable solutions. This case study details the successful deployment of a fully automated 1000 tons/day SSP/TSP phosphate production line for a major agribusiness client in Indonesia, showcasing a leap in inorganic fertilizer production capacity.

Client Overview & Strategic Challenge

The client, a well-established phosphate fertilizer producer in Southeast Asia, was at a capacity crossroads. Their existing SSP fertilizer production line was operating at 500 TPD, unable to meet rising regional demand for both Single Superphosphate (SSP) and Triple Superphosphate (TSP). Their goals were clear:

Double Production Output: Scale from 500 TPD to a robust 1000 TPD.

Product Line Flexibility: Seamlessly switch production between SSP and TSP fertilizers using a single, integrated phosphate fertilizer processing line.

Enhance Cost-Efficiency: Lower the cost-per-ton through advanced automation and superior energy utilization.

The Gofine Solution: A High-Yield, Flexible Production Line

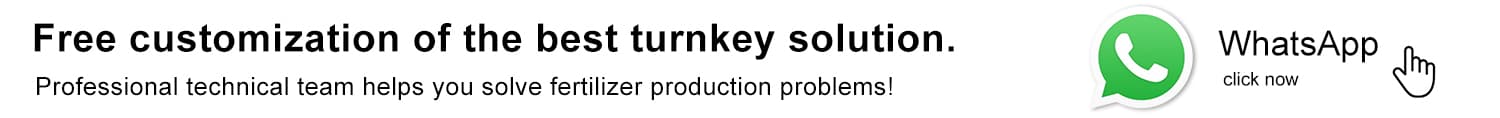

After a thorough technical audit, Gofine engineers designed and commissioned a turnkey granular fertilizer production line with a guaranteed capacity of 1000 tons per day. This wasn't merely an upscaling of equipment; it was a re-engineering of the entire superphosphate manufacturing process for maximum throughput and flexibility.

Key Components of the 1000 TPD Production Line:

Advanced Raw Material Preprocessing: A high-volume fertilizer crusher and mixer system ensures uniform particle size and precise acid-to-rock ratio, which is critical for reaction efficiency in both SSP and TSP processes.

Continuous Reaction & Curing System: Our proprietary continuous den and cone mixer technology replaced batch processing, enabling a non-stop flow of material and ensuring a complete chemical reaction—the cornerstone of a high-capacity chemical processing plant.

High-Capacity Granulation Unit: At the heart of the line is a heavy-duty fertilizer granulation equipment system that transforms the cured powder into strong, uniform granules, significantly reducing dust and improving product marketability.

Integrated Drying, Cooling, and Screening: A coordinated system efficiently handles the thermal treatment and sizing of the granules, ensuring product integrity and producing a consistent, premium-grade fertilizer.

Plant-Wide Automation: A central PLC controls the entire fertilizer production system, providing real-time data, precise process control, and minimal human intervention for stable, 24/7 operation.

Operational Results & Business Impact:

Within three months of commissioning, the new production line exceeded performance expectations.

Surpassed Capacity Target: Achieved a consistent output of 1,050-1,080 TPD, demonstrating the line's robust engineering.

Unlocked Operational Flexibility: The client can now efficiently schedule production runs for either SSP or TSP based on market demands, maximizing profitability.

Reduced Operating Cost: Automated controls optimized raw material and sulfuric acid consumption, leading to a 20% reduction in production cost per ton.

Enhanced Product Quality: Over 99% of the output meets the strictest granular size and hardness specifications, allowing the client to access premium markets.

Why Partner with Gofine Machine for Your Project?

This project underscores our position as a premier fertilizer plant contractor. We don't just sell machines; we deliver guaranteed production outcomes.

Proven Expertise in High-Capacity Lines: We specialize in designing and building large-scale phosphate fertilizer plants from 500 to 2,000 TPD.

End-to-End Service: From initial concept and process design to installation, commissioning, and operator training, we provide a seamless, single-point-of-contact service.

Focus on Your ROI: Our solutions are engineered for durability and efficiency, ensuring a rapid and substantial return on your capital investment.

Conclusion

This 1000 TPD SSP/TSP production line is a testament to how modern engineering can transform fertilizer manufacturing. It stands as a benchmark for high-capacity, flexible, and cost-effective phosphate fertilizer production.

Ready to Build Your High-Capacity Fertilizer Plant?

If your company is planning a new greenfield project or a major capacity expansion, let Gofine's expertise guide you to success.

Contact us today to request the full technical case study or to schedule a consultation with our engineering team.