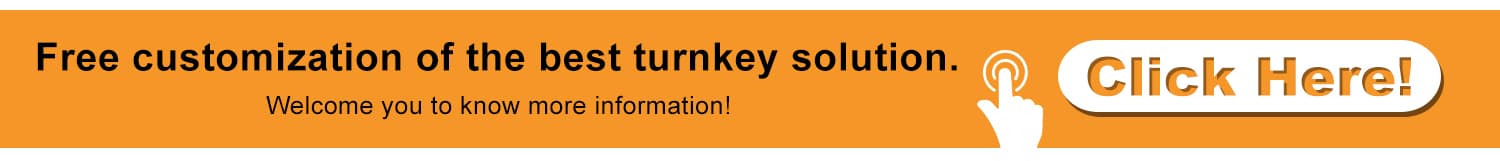

Organic Compound Fertilizer Production Line with A Daily Output of 5 Tons

2025-10-28As a professional fertilizer equipment manufacturer, we present this comprehensive guide to a 5-ton daily organic compound fertilizer production line. This scale is ideal for small to medium-sized enterprises, agricultural cooperatives, and farms looking to convert organic waste into high-value fertilizer. This article explores the complete setup, from raw material processing to final packaging, focusing on the core equipment that makes such an operation efficient and profitable.

Introduction to the 5-Ton Daily Production Line

A 5-ton daily organic compound fertilizer production line is designed for consistent, medium-scale output. This granulation production line efficiently processes various organic materials—such as animal manure, agricultural waste, and bio-solids—into uniform, nutrient-rich pellets. The entire fertilizer production line is engineered for reliability, ease of operation, and minimal maintenance, making it a practical choice for businesses entering the organic fertilizer market or expanding their existing capacity.

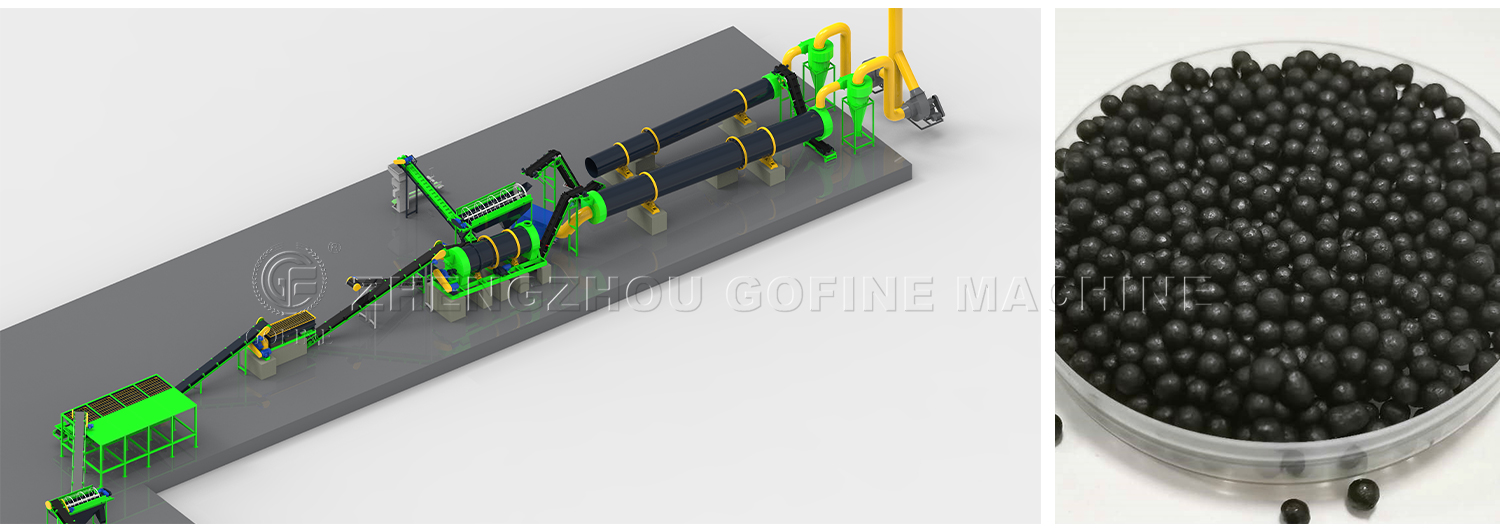

Core Equipment in the 5-Ton Daily Production Line

1. Compost Turner: The Foundation of Decomposition

The compost turner is critical in the initial stage of the fertilizer production line. It accelerates the aerobic decomposition of raw organic materials, ensuring efficient breakdown and pathogen elimination. For a 5-ton daily line, a self-propelled or hydraulic compost turner is recommended. It ensures thorough mixing, optimal aeration, and moisture control, reducing the composting cycle from months to just a few weeks.

2. Fertilizer Granulator: The Heart of Granulation

The fertilizer granulator is the centerpiece of the granulation production line. For a 5-ton daily output, a disc granulator is often the preferred choice due to its high efficiency, adjustable pellet size, and low energy consumption. The granulator transforms well-composted and crushed materials into uniform, sturdy pellets suitable for storage, transportation, and application.

3. Supporting Equipment for a Complete Line

Crusher: Reduces composted clumps into fine powder for smooth granulation.

Mixer: Ensures homogeneous blending of organic materials and additives.

Rotary Dryer & Cooler: Reduces moisture and stabilizes pellets for long-term storage.

Screening Machine: Separates undersized and oversized pellets for recycling or regranulation.

Coating Machine: Applies protective coatings to improve nutrient retention and dust control.

Automatic Packing Scale: Weighs and packages the final product for market readiness.

Advantages of This Production Line

Cost-Effective Investment: Tailored for 5-ton daily output, balancing capacity and budget.

Flexible Raw Materials: Capable of processing diverse organic wastes, including livestock manure, crop residues, and municipal sludge.

High Automation: Requires minimal manual intervention, reducing labor costs.

Eco-Friendly Operation: Supports waste recycling and reduces environmental pollution.

Compact Layout: Designed to fit limited spaces without compromising efficiency.

Process Flow of the 5-Ton Daily Production Line

Composting: Raw materials are piled and regularly turned using the compost turner for 15–20 days.

Crushing & Mixing: Fully composted materials are crushed and mixed to achieve uniformity.

Granulation: The prepared powder is fed into the fertilizer granulator to form pellets.

Drying & Cooling: Pellets are dried and cooled to achieve the desired moisture content and hardness.

Screening & Coating: Qualified pellets are selected and coated for enhanced quality.

Packaging: The final organic compound fertilizer is weighed and bagged for sale.

Investment and Operational Considerations

The total investment for a 5-ton daily organic compound fertilizer production line varies based on equipment configuration and automation level. Key cost components include the compost turner, fertilizer granulator, and auxiliary machines. Operational costs involve power consumption, labor, maintenance, and raw material procurement. With proper management, the return on investment can be achieved within 1–2 years, thanks to the growing demand for organic fertilizers.

A 5-ton daily organic compound fertilizer production line offers an excellent entry point or expansion opportunity in the sustainable agriculture sector. By integrating a reliable compost turner and an efficient fertilizer granulator, this granulation production line ensures consistent output of high-quality organic compound fertilizer. As a trusted manufacturer, we provide end-to-end solutions—from design and installation to training and support—helping you build a successful and profitable fertilizer production business.

Contact us today to get a customized layout and quotation for your 5-ton daily organic compound fertilizer production line!