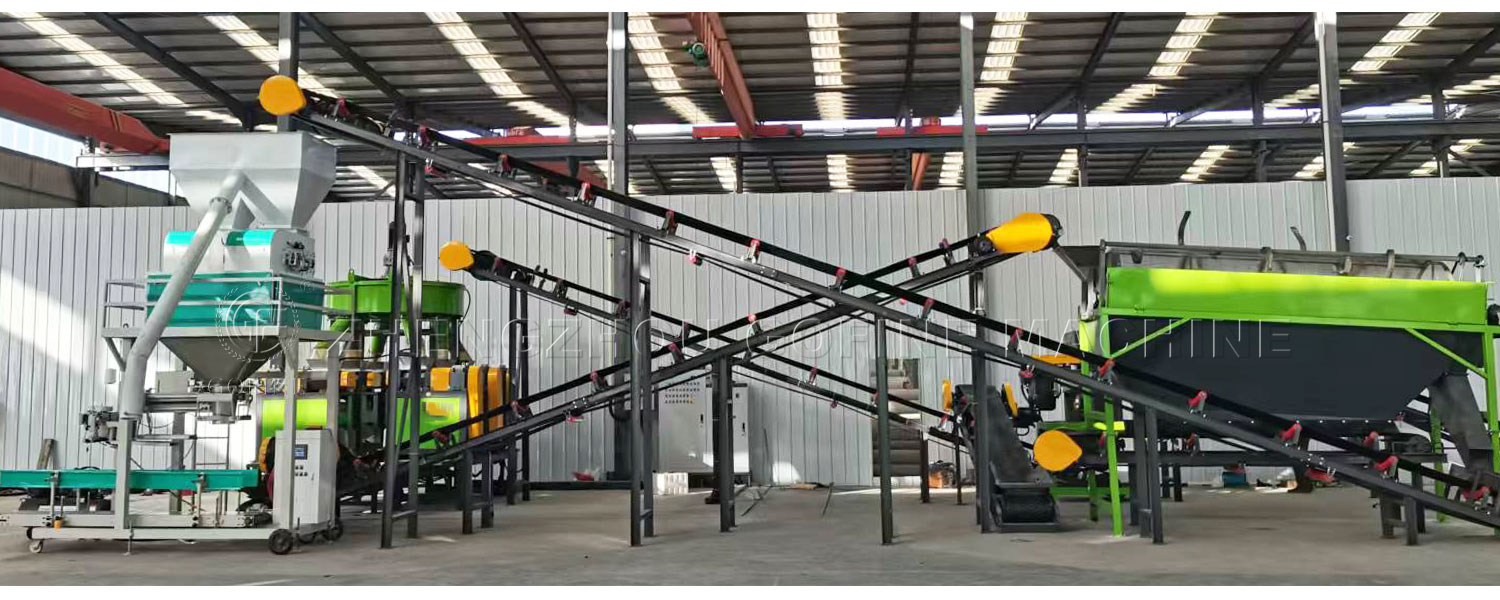

Efficient Dry Extrusion Granulation SSP Production Line

2026-01-30SSP Granulation Line Overview with Extrusion Granulator

An SSP production line utilizing an Extrusion Granulator (commonly a Double Roller Press Granulator) employs a completely dry granulation technology. This method is distinct for its simplicity and energy efficiency, as it forms dense SSP granules or briquettes through mechanical pressure alone, eliminating the need for liquid binders or subsequent drying. The process involves compacting dry SSP powder between two counter-rotating rollers under high pressure, forming a sheet that is then crushed and screened into uniform, irregularly shaped granules. This line is ideal for producing high-bulk-density SSP products with low moisture content.

Key Features of an Extrusion Granulator-Based SSP Line

Dry Process, No Drying Required: The most significant advantage is the elimination of the drying and associated cooling stages, leading to substantial savings in energy, equipment cost, and factory footprint. It is a truly compact fertilizer plant solution.

High Production Efficiency & Continuous Operation: The double roller press granulator operates continuously at high speed, offering excellent output rates for its size. It is well-suited for automated, 24/7 production runs.

Produces High-Density, Low-Dust Granules: The granules produced are extremely hard and dense, resulting in minimal dust generation during handling, storage, and application. They also have excellent storage properties.

Lower Operational Complexity: With fewer process stages (no mixing with liquid, no drying/cooling), the entire line is simpler to control and maintain, reducing labor and operational overhead.

Production Process and Workflow

Raw Material Crushing & Sieving: Dry SSP powder is first processed through a crusher and a screening machine to ensure a very fine and uniform particle size, which is critical for effective compaction and granule strength.

Pre-Compaction Feeding: The fine powder is fed into the Extrusion Granulator's feeding system, which ensures a consistent and uniform flow of material into the nip of the rollers.

Compaction & Granule Formation: Inside the double roller press, the powder is compressed under extreme pressure (typically tens of megapascals) between the two rollers, which have engraved pockets. This forms a solid sheet or briquettes.

Crushing & Sizing: The compacted sheet or large briquettes exit the press and are broken down into smaller, uniform granules by a crushing mill integrated with the system.

Screening & Recycling: The sized granules are passed over a vibrating screen. On-spec SSP granules are sent to packaging. Fine powder is automatically recycled back to the pre-compaction feed system, ensuring zero waste.

Packaging: The final, dry, and dense granules are directly conveyed to an automatic packing scale for bagging.

In summary, the potassium phosphate production line based on extrusion granulation technology, with its unique dry process, significant energy-saving advantages, and high degree of automation and continuous operation, offers unparalleled value to customers seeking efficient, energy-saving, and compact production. It is particularly suitable for processing heat-sensitive fertilizers or those requiring minimized energy consumption. For investors concerned about long-term operating costs, limited plant space, or planning to produce high-density, low-dust potassium phosphate products, this production line represents the cutting edge of efficiency in modern fertilizer manufacturing. Click to inquire and learn how our extrusion granulators can help you build a more cost-competitive production system.