Silica Cat Litter Manufacturing Process | Disc Granulator & Pelletizing Equipment

2025-07-24Efficient Silica Cat Litter Production with Disc Granulation Technology

Silica cat litter, also known as crystal cat litter or silica gel litter, is one of the most popular pet hygiene products on the global market. Known for its high absorption, odor control, and dust-free performance, silica-based cat litter is a preferred choice for premium pet brands.

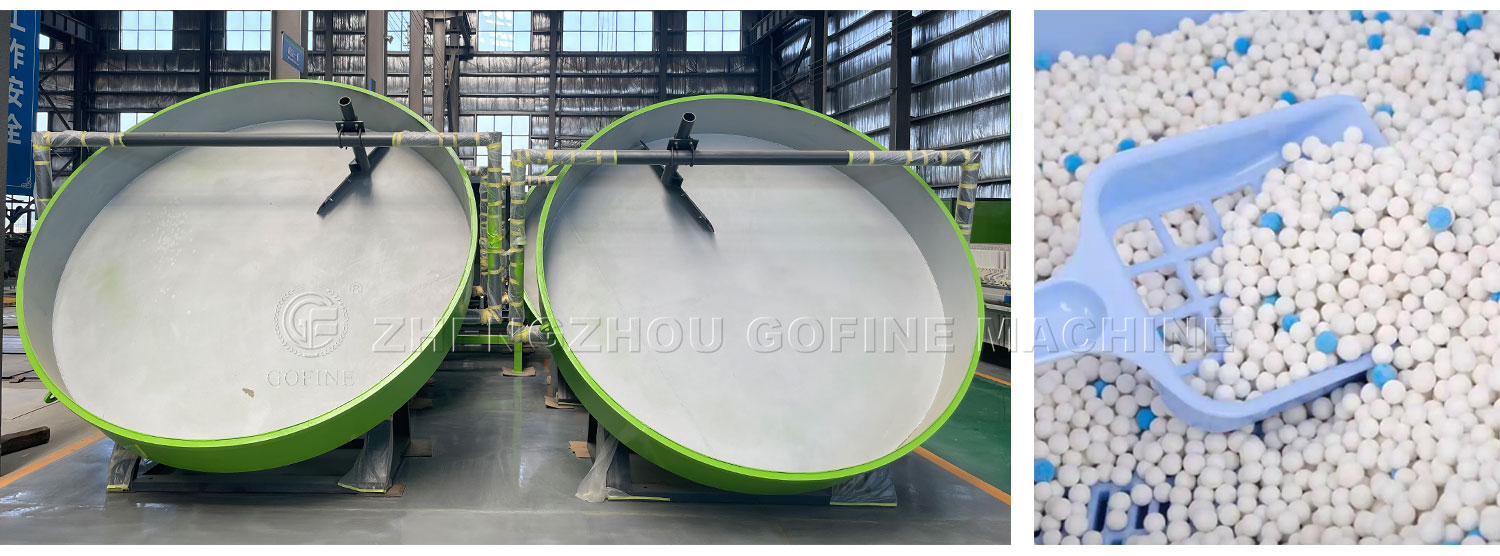

At Gofine Machine, we offer a comprehensive silica cat litter manufacturing solution — from raw material processing to final packaging — with a focus on disc granulation technology for producing uniform, durable litter granules.

What Is Silica Cat Litter Made From?

Silica cat litter is typically made from sodium silicate, which is processed into silica gel granules. These granules are porous, lightweight, and capable of absorbing liquids and odors from pet waste.

Some formulas may also include:

Color indicators (for health monitoring)

Deodorizing agents (baking soda, activated carbon)

Fragrance additives

Anti-bacterial or anti-clumping coatings

Silica Cat Litter Manufacturing Process Overview

Below is a standard process for producing silica gel cat litter pellets:

1. Raw Material Preparation

Sodium silicate is processed into a gel form, then dried into a powder

Additives like fragrances or color indicators are blended uniformly

2. Mixing

Use a horizontal mixer or double-shaft mixer to blend silica powder with binders or modifiers before granulation

3. Pelletizing with Disc Granulator

The mixture is fed into a disc granulator (pan granulator)

With controlled water spray and disc rotation, powder forms into uniform, semi-spherical granules (2–6 mm)

This method ensures high shaping rate, low breakage, and adjustable pellet size

4. Drying

The pellets are dried in a rotary dryer to reduce moisture and harden the granules

5. Screening

Use a rotary screener to remove oversized or undersized particles

Qualified pellets are sent to the next stage; unqualified ones are reprocessed

6. Dust Removal & Coating (Optional)

Apply anti-dust or anti-static coating for improved user experience

7. Packaging

Final silica cat litter is packed using automatic bagging machines (1kg, 5kg, 10kg, etc.)

Key Equipment for Silica Gel Cat Litter Production

| Equipment | Function |

| Mixer | Blends silica powder and additives evenly |

| Disc Granulator | Forms consistent round cat litter pellets |

| Water Spray System | Controls moisture for pellet shaping |

| Rotary Dryer | Dries and hardens the granules |

| Rotary Screener | Classifies granules by size |

| Dust Collector | Reduces airborne particles |

| Packing Machine | Automates bagging and sealing |

Why Use a Disc Granulator for Silica Cat Litter?

High pelletizing rate (≥90%)

Adjustable granule size (2–6 mm)

Low energy consumption, easy maintenance

Compact design, ideal for silica materials

Improves product shape and durability

Benefits of Silica Cat Litter Granules

Silica cat litter is a high-end, premium cat litter that is well-competitive in the market.

Superior liquid absorption (up to 80% of its weight)

Low dust emission — ideal for sensitive pets

Excellent odor control

Long-lasting usage per scoop

Perfect for private label and OEM pet brands

We provide turnkey solutions, including disc granulators and comprehensive cat litter production technical support.

Welcome to contact me at any time! Get your silica cat litter factory plan for free

Support old factory transformation and upgrading service