Wet Granulation Efficiency: Optimizing Your Organic Fertilizer Production Line

2025-12-18For commercial organic fertilizer manufacturers, operational efficiency directly determines profitability. Wet granulation has become the preferred process not by chance, but because it offers a systematic engineering solution that optimizes the entire production line for maximum output, control, and scalability.

High-Capacity Output with Superior Yield

The core of wet granulation's efficiency lies in its high conversion rate and throughput:

Maximized Granulation Rate:

Equipment like the rotary drum granulator creates an ideal tumbling environment where up to 95% of raw material is converted into on-spec pellets in a single pass.

Continuous Processing:

Unlike batch methods, wet granulation systems operate continuously, enabling high-capacity production of 5-30 tons per hour in a single line.

Minimized Recycle Load:

The efficient agglomeration process significantly reduces the amount of fines needing recycling, streamlining material flow and increasing net output.

Precise Process Control for Consistent Quality

Modern wet granulation provides unparalleled control over production variables:

Real-Time Adjustment:

Key parameters—binder spray rate, drum speed and inclination—can be fine-tuned during operation to adapt to different raw material blends.

Automated Integration:

The process seamlessly connects with upstream automatic batching systems and downstream drying units, creating a cohesive fertilizer manufacturing flow.

Batch-to-Batch Consistency:

This control ensures uniform pellet size (typically 3-4mm) and composition, which is critical for product reliability and brand reputation.

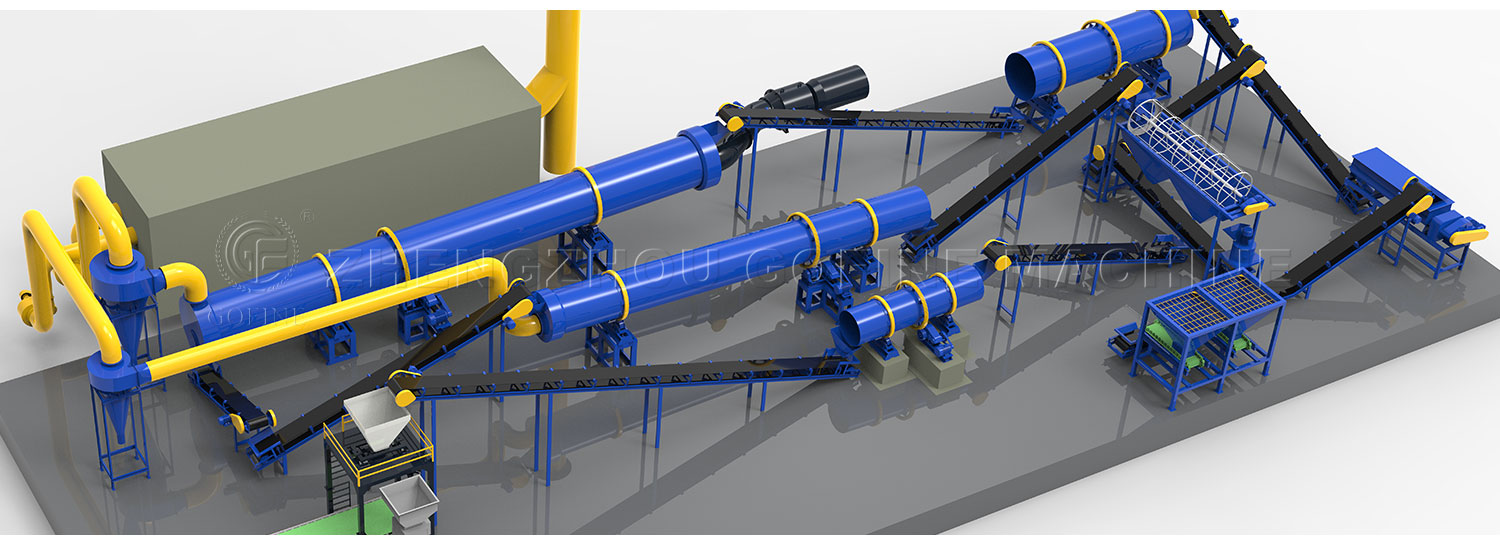

Integrated System Design for Operational Excellence

Wet granulation fits perfectly into complete production line engineering:

Moisture Synergy: It effectively utilizes the inherent moisture (25-35%) in pre-composted materials, reducing additional water needs.

Optimized Drying: The subsequent drying stage, while requiring energy, is highly efficient in modern rotary dryer systems that gently reduce moisture without damaging pellet structure.

Scalable Architecture: Production capacity can be increased through equipment sizing and duplication, supporting business growth from small plants to large-scale fertilizer production facilities.

Operational Advantages of Wet Granulation Systems

| Aspect | Wet Granulation Advantage | Impact on Production |

| Output Consistency | Continuous process with stable output | Predictable production scheduling |

| Quality Control | Real-time parameter adjustment | Reduced off-spec product (<2%) |

| Labor Efficiency | High automation potential | Lower labor costs per ton |

| Scalability | Modular design approach | Easier capacity expansion |

Conclusion: The Efficiency Standard for Growth

For manufacturers focused on building a reliable, high-output organic fertilizer business, wet granulation represents the efficiency benchmark. Its combination of high yield, precise control, and system integration provides a proven pathway to scalable, profitable operations in the competitive organic inputs market.