Animal Waste Chicken Manure Organic Fertilizer Granulator Machine Design

2025-10-15In the world of sustainable agriculture and waste management, transforming animal waste, particularly chicken manure, into valuable organic fertilizer is a growing priority. This process not only addresses environmental concerns but also creates a circular economy. At the heart of this transformation lies a critical piece of equipment: the Organic Fertilizer Granulator Machine. As a leading manufacturer, we are proud to introduce our latest innovation in animal waste chicken manure organic fertilizer granulator machine design, engineered for efficiency, durability, and superior performance.

The Need for Specialized Granulation

Chicken manure is a rich source of nitrogen, phosphorus, and potassium. However, in its raw form, it's challenging to handle, transport, and apply evenly to fields. Granulation solves these issues by converting the processed manure into uniform, dust-free, and easy-to-spread pellets. This is where a specialized fertilizer granulating machine becomes indispensable. Our new granulator is specifically designed to handle the unique texture and composition of composted chicken manure, ensuring high-quality fertilizer production.

Key Features of Our New Granulator Design

Our engineering team has focused on creating a machine that meets the modern demands of organic fertilizer producers. Here are the standout features of our new design:

1. Advanced Granulation Mechanism: Unlike generic pelletizers, our machine utilizes a combination of high-pressure agitation and tumbling action. This ensures that the moist, composted manure forms dense, spherical pellets with a low breakage rate. This specific mechanism is a result of extensive research into the binding properties of animal waste.

2. High Corrosion-Resistant Materials: Chicken manure is inherently corrosive. Our fertilizer granulator is constructed with high-grade stainless steel or specialized alloys in all critical contact areas. This significantly enhances the machine's lifespan and reduces maintenance costs, providing a better return on investment.

3. Adjustable Pellet Size: Flexibility is key for catering to different market needs. Our granulating machine allows for easy adjustment of the final pellet size, typically between 2mm and 6mm. This makes the end product suitable for various application methods, from large-scale broadcasting to precision gardening.

4. High Organic Matter Pass Rate: A common challenge in organic fertilizer granulation is the destruction of beneficial microorganisms due to excessive heat or pressure. Our design optimizes the temperature and pressure control during the process, preserving the organic matter's integrity and ensuring a high-quality, biologically active fertilizer.

5. Energy-Efficient Operation: We have integrated a high-torque, variable-speed drive system that reduces overall power consumption. This makes our new granulator not only productive but also cost-effective to run, aligning with sustainable operational practices.

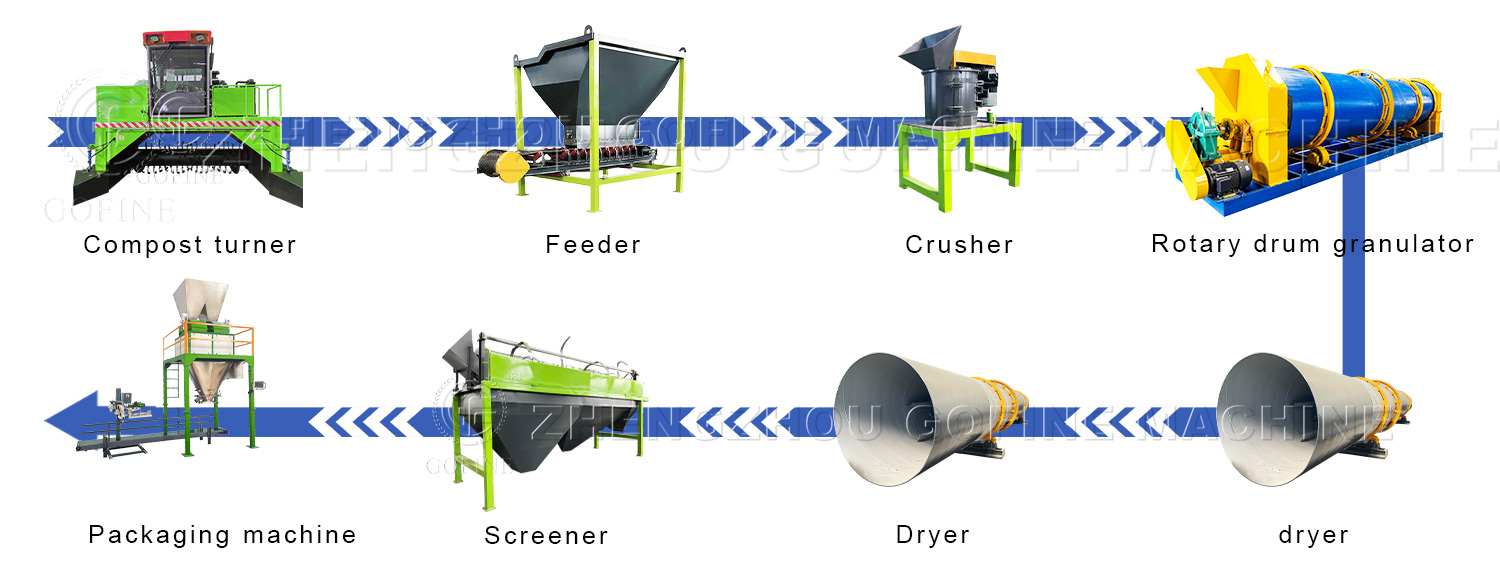

The Granulation Process: From Waste to Resource

Understanding the process helps highlight the importance of a well-designed machine. The journey begins with properly composted and fermented chicken manure, which is crushed into a fine powder. This powder is then fed into our fertilizer granulating machine. Inside the granulator drum, a fine mist of water or a natural binder is added. As the drum rotates, the material is tumbled and compressed, forming the pellets through a combination of centrifugal force and mechanical pressure. The resulting "green" pellets are then sent for drying and cooling to achieve their final, stable form.

Fertilizer Granulation Process

Why Choose Our Fertilizer Granulating Machine?

The market is filled with various pelletizers, but our focus on animal waste chicken manure organic fertilizer granulator machine design sets us apart. We don't offer a one-size-fits-all solution. Our equipment is built from the ground up to handle the specific challenges of organic, fiber-rich materials like chicken manure.

-

Higher Yield: Achieve a granulation rate of over 90%, minimizing raw material waste.

-

Robust Reliability: Built for 24/7 operation in demanding environments.

-

Ease of Maintenance: A user-friendly design with easy-access parts simplifies cleaning and servicing.

Investing in the right technology is crucial for success in the organic fertilizer industry. Our innovative new granulator represents the next step in efficient and reliable fertilizer granulating machine technology. It is more than just a machine; it's a partner in your mission to recycle waste and produce premium organic fertilizer.

If you are looking to upgrade your production line or start a new venture in organic fertilizer from chicken manure, contact us today. Let us show you how our cutting-edge granulator machine design can enhance your productivity, profitability, and environmental contribution.