NPK Organic Compound Granule Fertilizer Production Process Machinery

2024-03-01The Difference Between Fertilizer Granules and Compost

Fertilizer granules are usually processed chemical synthetic fertilizers. The main ingredients include various nutrients such as nitrogen, phosphorus, and potassium, as well as other auxiliary ingredients. Compost is an organic fertilizer made from organic waste through natural decomposition and fermentation. The raw materials include food waste, manure, straw, and other organic materials.

Fertilizer granules are usually processed chemical synthetic fertilizers. The main ingredients include various nutrients such as nitrogen, phosphorus, and potassium, as well as other auxiliary ingredients. Compost is an organic fertilizer made from organic waste through natural decomposition and fermentation. The raw materials include food waste, manure, straw, and other organic materials.

Fertilizer granules are suitable for top dressing and base fertilizer application of various crops. They can provide nutrients directly absorbed by plants and quickly meet the needs of crops. Compost is mainly used for soil improvement and organic matter supplementation. It can improve the water and fertilizer retention performance of the soil, promote soil microbial activity, and indirectly improve the plant growth environment.

NPK Production Process

NPK fertilizer is a compound fertilizer that usually contains three main nutrient elements: nitrogen (N), phosphorus (P), and potassium (K).

These three nutrients are the main nutrients necessary for crop growth. It can help crops grow healthily, increase yield, and improve fertilizer quality.

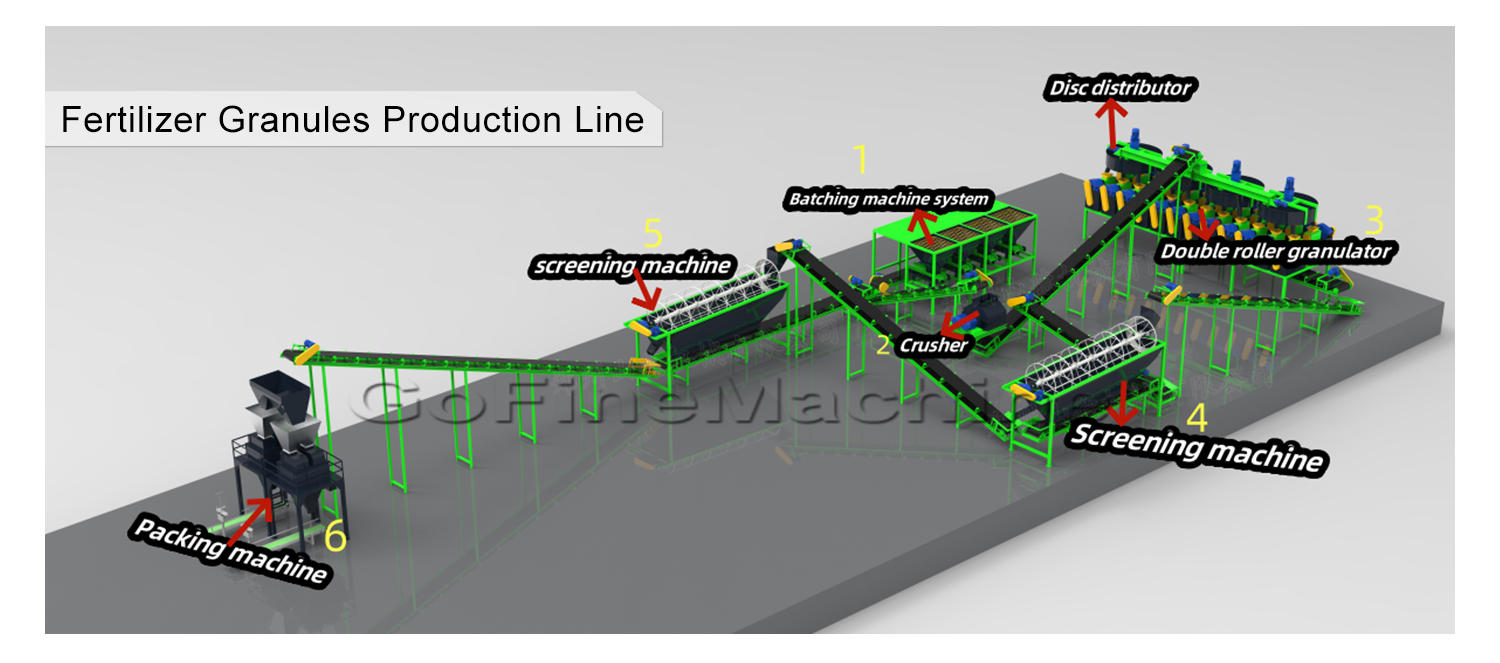

If you want to produce NPK fertilizer granules, then you mainly prepare multiple fertilizer production processes.

Raw material proportioning : According to the formula requirements, the prepared raw materials are accurately batched through the batching machine and transported to the next process through the belt conveyor.

Mixing and crushing : The purpose of using crushers and mixers is to better integrate the raw materials and ensure that the materials can be mixed evenly.

Granulation : The processed materials can be processed into regular-shaped spherical or oblate granular fertilizers through granulation equipment, such as disc granulators, double roller extrusion granulators, drum granulators, etc.

Drying : In order to make the appearance of fertilizer granules more beautiful, drying equipment is usually used to increase the hardness of the fertilizer granules and facilitate long-term storage and transportation.

Screening and packaging : Screen the dried NPK granular fertilizer to remove particles that do not meet the regulations. An automatic weighing and packaging machine is used to bag the finished granules, and the palletizing robot will transport the finished bags of fertilizer granules to the target location.

Depending on the materials and factory buildings, adjustments and improvements will be made based on different production equipment and process requirements in actual production. Ensure the production of high-quality fertilizer granular products.

Slow-release Fertilizer Granule Processing Process

As a special type of fertilizer, slow-release fertilizer has the advantages of slow release of nutrients and long-lasting fertilizer effect.

Compared with the rapid effects of NPK fertilizers, slow-release fertilizers can provide continuous nutrient support for crops over a longer period, helping to reduce nutrient loss and waste and improve fertilizer utilization efficiency.

Granulation Equipment for Slow-release Fertilizer Granules

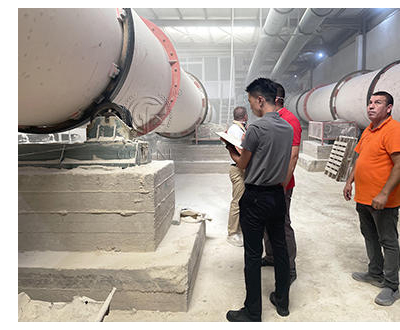

Wet granulation - Rotary drum granulator

The rotary drum granulator adopts the wet granulation method. Through the high-speed rotation and friction inside the drum, the material particles are squeezed to form round and full fertilizer granules.

Dry granulation -Double roller extrusion granulator

The double-roller extrusion granulator can produce fertilizer granules at normal temperatures without a drying process and has low energy consumption. Flat round fertilizer granules can be formed in one squeeze. When used with a rounding machine, oblate granules can be processed into spherical granules. It can be combined with supporting fertilizer equipment to form a granular fertilizer production line to achieve continuous and high-efficiency production.

Fertilizer Storage Methods

Granular fertilizers are generally easier to store and transport than powdered fertilizers. Because the form and quality of granular fertilizers are more stable and less likely to float, clump, and get damp, this greatly reduces the risk of fertilizer deterioration during storage. The fertilizer granules are compressed into granules during the production process, which can effectively maintain the nutrients in the fertilizer and avoid volatilization and loss of nutritional value. When applying fertilizer, the amount of fertilizer can be controlled more accurately and spread evenly to avoid waste and excessive fertilization, while also improving work efficiency.

How to get high-quality fertilizer granules

Rotary screening machine is an important piece of equipment for obtaining high-quality fertilizer granules.

You need to choose the mesh size of the screening machine based on the production scale and the requirements of the fertilizer granules.

A high-quality screening machine will increase your production efficiency with half the effort. Otherwise, problems such as screen clogging and uneven screening will occur. For some fertilizer granules with higher requirements, multiple screenings can be performed to gradually improve the quality and purity of the granules, allowing you to gain a greater competitive advantage in the fertilizer market.