what is process of fertilizer granulator

2024-04-09Dry Granulator and Wet Granulator

Compound organic fertilizer granulation is processing raw materials (such as chemical fertilizer raw materials, organic fertilizers, inorganic fertilizers, compound fertilizer etc.) into granular shapes through fertilizer granulation equipment, making the fertilizer easier to store, transport, and apply, and improving fertilizer utilization efficiency.

Generally speaking, the compound organic fertilizer granulation process mainly includes dry granulator and wet granulator. The main difference is whether the processing of the fertilizer requires the addition of water or binders.

Dry Granulation Process

1. Raw materials: Generally, raw materials with a moisture content of less than 10% are used for granulation, such as nitrogen, phosphorus potassium, feed vitamins, bentonite, etc.

2. Granulation: Dry granulation processes the raw materials into regular-shaped organic compound fertilizer granulaes through physical extrusion. The granulation process does not require any additives. The granulated organic compound fertilizer granules do not need to be dried and cooled and can be packaged after screening. It has the characteristics of high efficiency and low energy consumption.

Dry granulation technology can be adjusted and optimized according to different raw materials and product requirements to facilitate the production of high-quality organic compound fertilizer products to meet the needs of planting, agriculture, and other fields.

Advantages of Double Roller Granulator Fertilizer Machine

The double roller granulator is a popular organic compound fertilizer granulation equipment.

1. High efficiency: The double roller granulator machine adopts the physical extrusion granulation method, which can extrude granular fertilizer in one go, with high production efficiency.

2. Regular particles: The fertilizer granules processed by the double roller granulator are uniform in size and regular in shape.

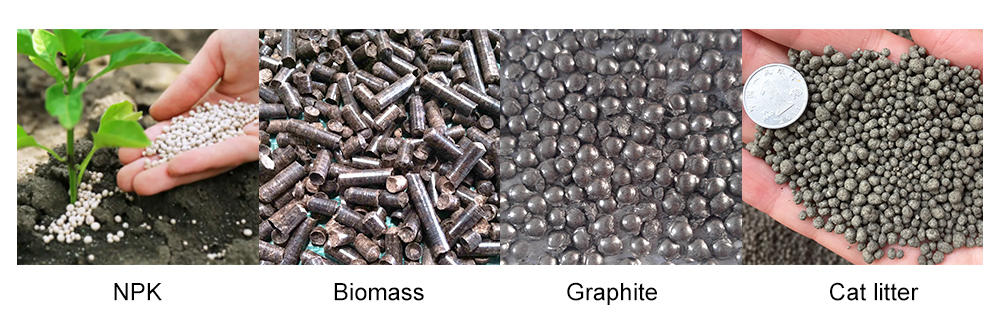

3. Wide range of applications: The double roller granulator fertilizer machine is suitable for granule processing of various powdery raw materials, including organic fertilizers, compound fertilizers, NPK, urea, feed vitamins, cat litter, etc.

4. Easy to operate: The double roller granulator fertilizer making machine is easy to operate and maintain, and the production process and granules size can be adjusted as needed.

In general, the double roller granulator fertilizer making machine has the advantages of high performance, good uniformity, wide application range, energy saving and environmental protection, simple operation, low cost and strong adaptability. It is a commonly used manufacturing machine in the fertilizer, chemical, pharmaceutical and other industries. granular equipment.

Wet Granulation Process

Different from dry granulation, the wet granulation process requires spray granulation equipment to make the material molecules more closely embedded.

The organic compound fertilizer granules produced by the wet granulator have higher moisture content. Therefore, you need to use a dryer and a cooler to make the fertilizer granules harder after granulation.

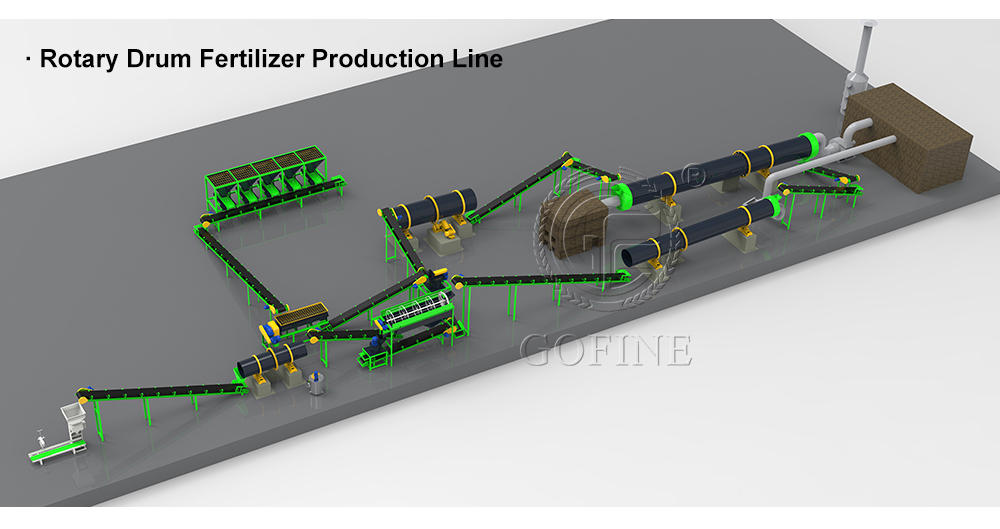

The best-selling wet granulators machine include disc granulators fertilizer equipment and rotary drum granulators fertilizer machine.

Advantages of Rotary Drum Granulation

The rotary drum granulator can be used for the production and processing of organic fertilizers, inorganic fertilizers and compound fertilizers. It is suitable for cold and hot granulation and large-scale production of high, medium and low concentration compound fertilizers. The rotary drum granulator uses the rotation of the drum to drive the fertilizer raw material molecules to rub, squeeze, and inlay in the drum, gradually forming spherical particles. Compared with dry granulation equipment, the surface of wet granulation fertilizer particles is smoother and less likely to agglomerate.

If you have higher requirements for the surface smoothness of the particles and the simplicity of the process operation, a rotary drum granulator may be more suitable.

When you want to choose a suitable fertilizer granulation equipment, you need to consider the following aspects:

1. Production scale: First of all, you need to consider the production scale and do not choose fertilizer granulation equipment that is too large or too small.

2. Raw material selection: According to the moisture content and viscosity of the fertilizer raw materials, you need to choose the most suitable fertilizer granulation process according to different materials, such as dry granulation or wet granulation.

3. Production cost: Considering the price and operating cost of the equipment, choosing better quality fertilizer equipment can help you reduce unnecessary expenses and facilitate longer use.

4. Production efficiency: Ensure that the equipment can meet production needs and improve production efficiency.

5. After-sales service: Consider whether the fertilizer equipment supplier’s after-sales service is complete and whether it can provide professional technical support and rich experience.