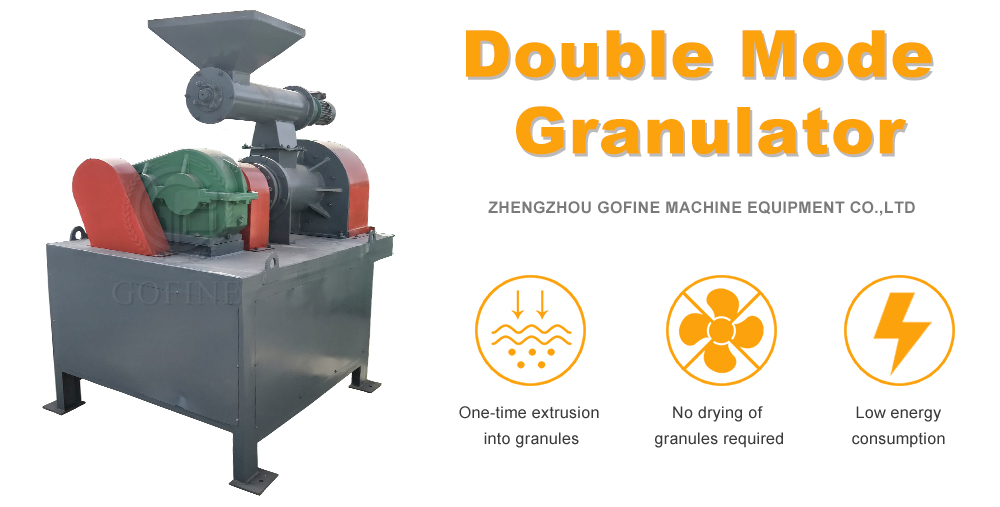

Double Mode Granulator Fertilizer Making Machine

- Information

Introduction of Double Mode Pellet Making Machine

The double-mode granulator integrates the ring die and the flat die. Equipped with a constant speed feeder, the front end of the mold can be forced to push the material, and the energy consumption is lower than that of the flat die granulator. The granulated pellets do not need to be dried, the surface is smooth, the hardness is moderate, and the granules thickness can be selected from 4-8mm in diameter. The fertilizer granulation equipment has a high degree of automation, high cost-effectiveness, and the pelleting rate is as high as 95%. It is widely used in the direct granulation production of organic substances such as poultry manure, urban sludge, domestic garbage, sugar factory filter sludge, distiller's grains and bean dregs, and plant ash.

Feature of Double Mode Pellet Making Machine

1. High cost performance: large output, low investment, small footprint.

2. Low energy consumption: the finished granules do not need to be dried, the surface is smooth and the hardness is moderate.

3. High ball forming rate: the ball forming rate is as high as 95%, and it has wide adaptability to raw materials.

4. High organic content: it can be granulated directly without any additives, and the organic content is 100%.

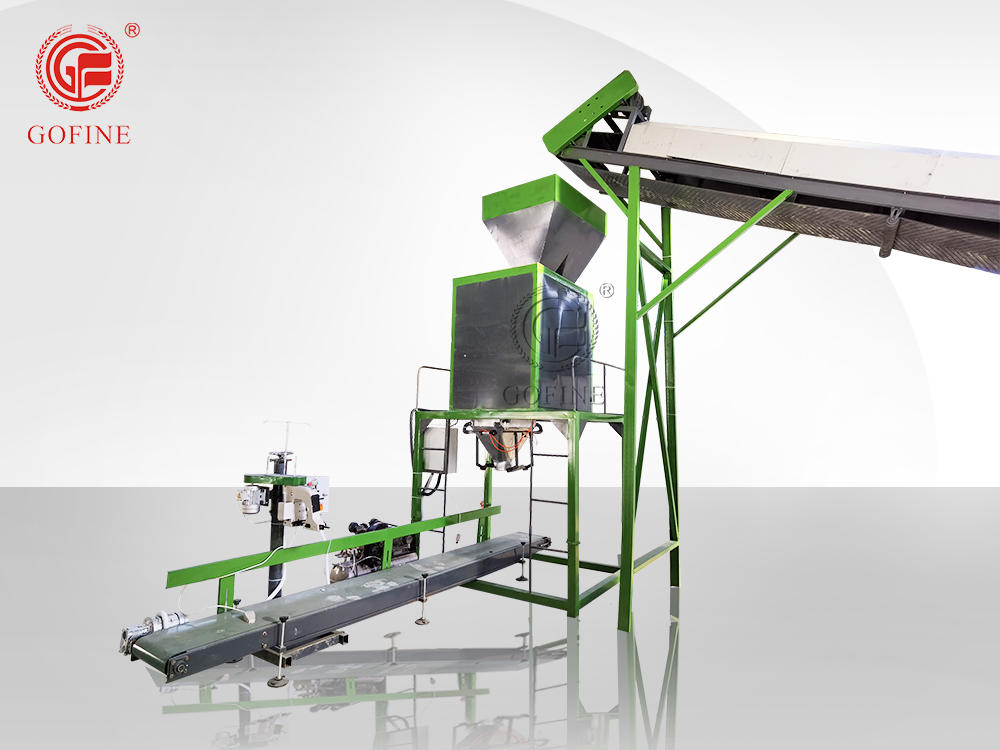

5. High automation: It can be combined with other equipment to form a granular fertilizer production line, which is easy to operate and saves manpower.

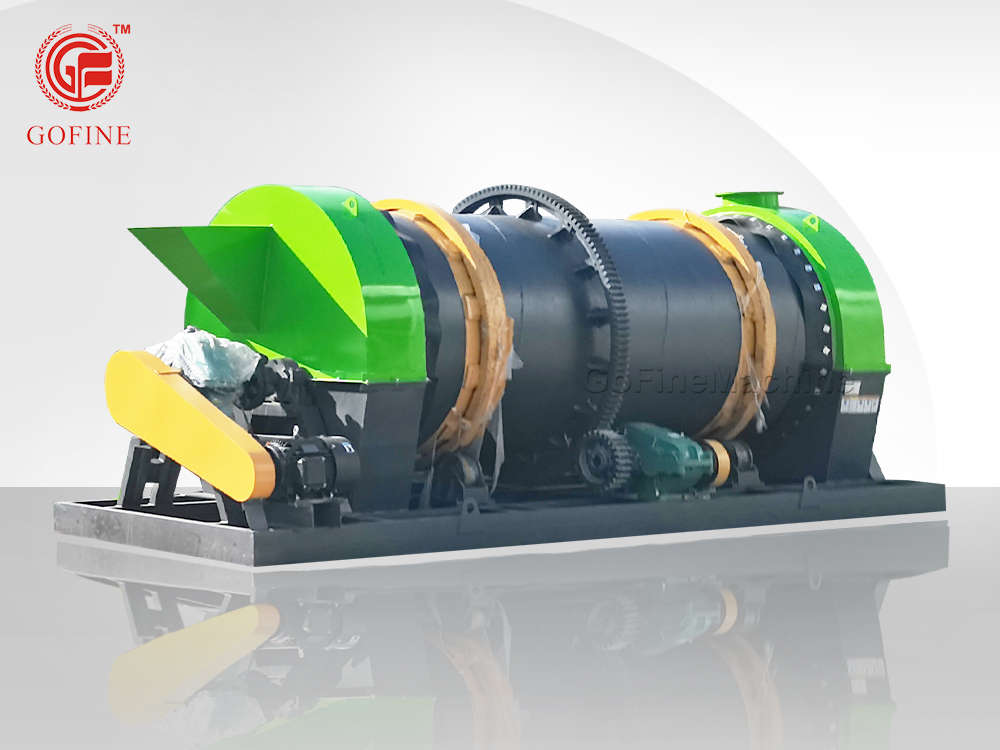

Working Process of Double Mode Pellet Making Machine

The double-mode fertilizer granulator adopts the extrusion granulation method, which is extruded into columnar granules at one time. During the granulation process, the friction between the material and the machine evaporates part of the water, so that the water content of the finished granules is low, and there is no need to dry after granulation. The equipment is equipped with two sets of extrusion dies, a ring die and a flat die. The material enters from the feed port, is pushed by the screw, and is extruded out of the mold by the pressure roller. Compared with the granulator with only one extrusion die, the double-die granulator has higher output and faster speed. It can not only produce fertilizer granules, but also process feed and combustion granules, realizing the multi-purpose of one machine.

Technical Parameter of Double Mode Pellet Making Machine

| Model | Power (kw) | Capacity (t/h) | Pellet ratio (t/h) |

| 450 | 30+2.2 | -5 | >95% |

| 650 | 45/55+4 | -8 | >95% |

Product Details of Double Mode Pellet Making Machine