Disc Granulator Organic Inorganic Fertilizer Production Line

- Information

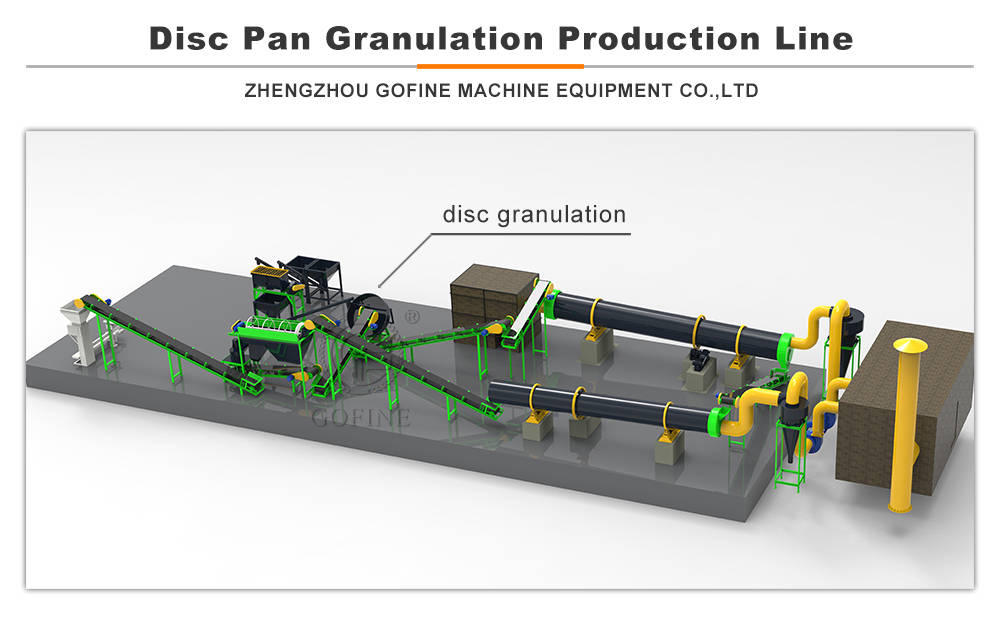

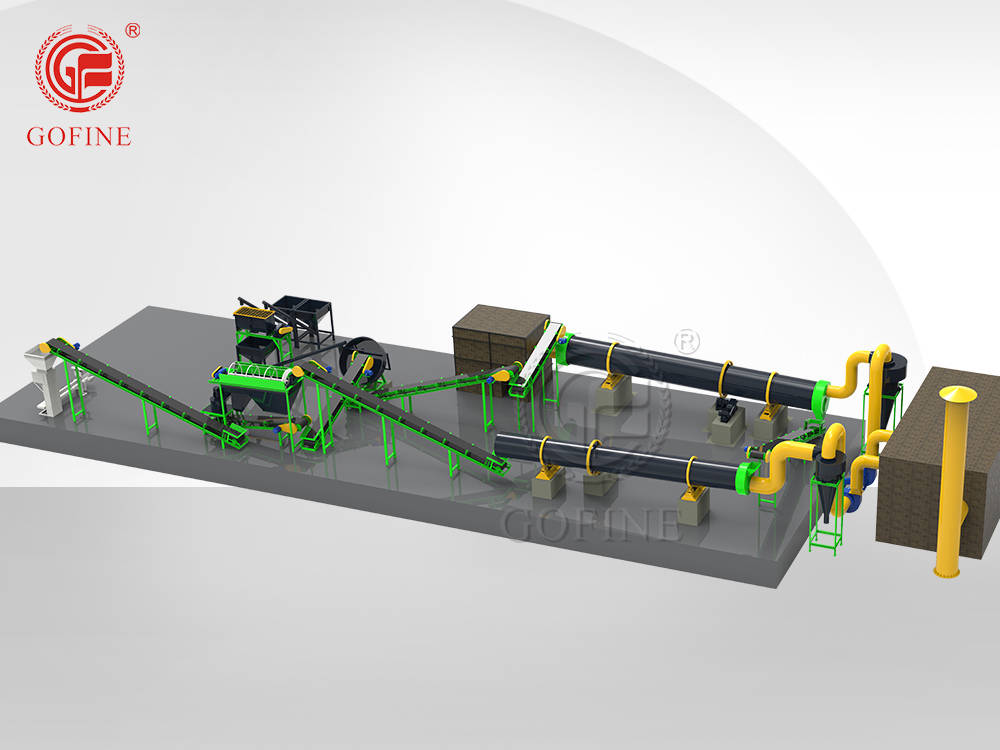

Introduction of Disc Granulating Organic Inorganic Fertilizer Production Line

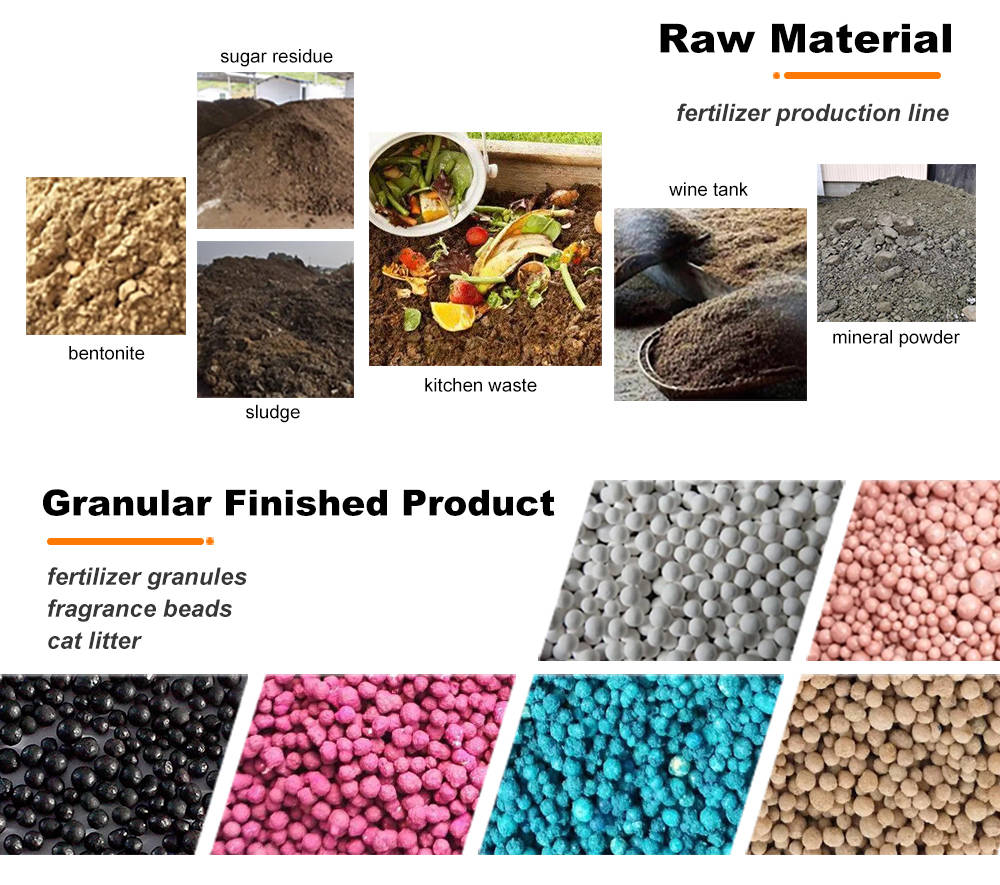

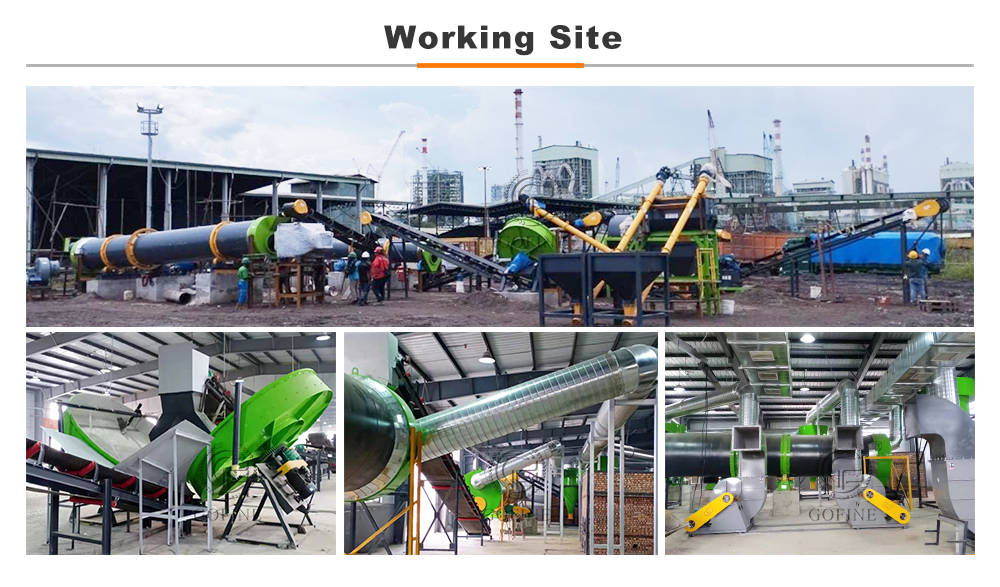

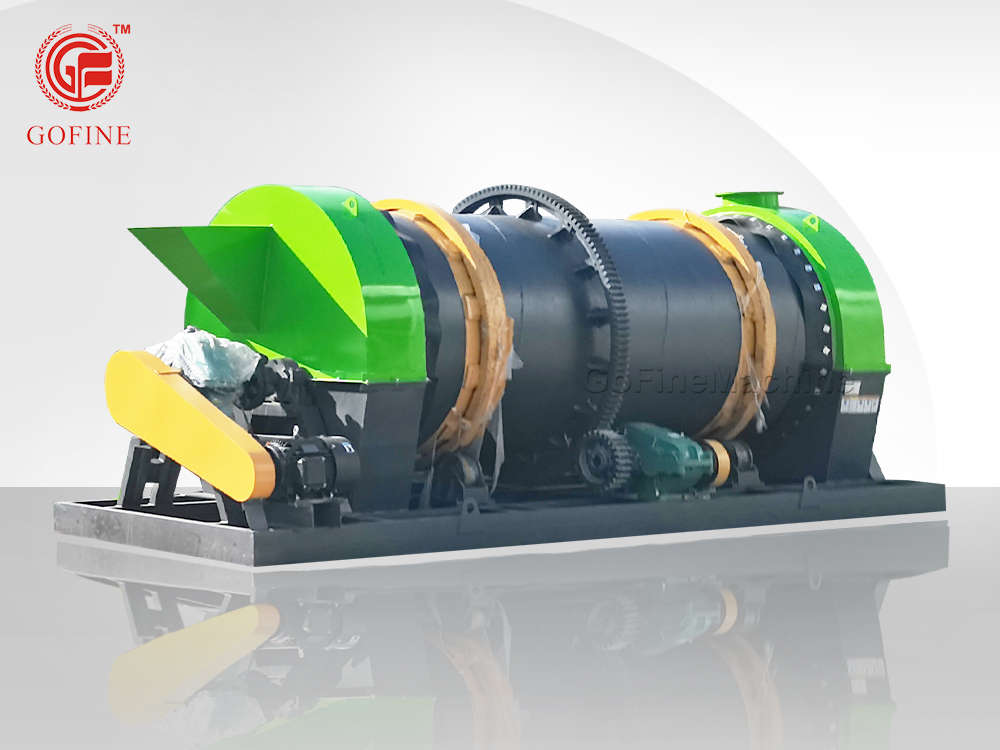

The disc granulation production line is a piece of equipment specially used to produce organic and inorganic granular fertilizers. This production line can carry out a series of manufacturing processes such as mixing, crushing, stirring, granulating, drying, screening and packaging of materials. The disc granulator adopts wet granulation method and uses the principle of rolling and growing materials to process powdered materials into uniformly shaped spherical granular fertilizers. The balling rate is as high as 93%, and it uses an unpowered scraper with low energy consumption. The disc granulation production line can not only produce fertilizer granules, but also bentonite cat litter granules, laundry fragrance beads, snow melting agents, desiccants, etc. To achieve automated and continuous production, corresponding auxiliary equipment can be configured, such as dust removal systems, to ensure the health and safety of the production environment and employees.

Feature of Disc Granulating Organic Inorganic Fertilizer Production Line

1. High balling rate: The balling rate of the disc granulator is as high as 93%, and the material residue rate is low.

2. High production capacity: The disc granulator has fast granulation speed and can meet the needs of large-scale granular fertilizer production.

3. Uniform particles: During the granulation process, the raw materials grow up through rolling inlays, and the finished particles become more uniform.

4. Lower energy consumption: It adopts a powerless scraper design, which has lower energy consumption than other granulation equipment.

5. No additives required: Using wet granulation process, no additives are needed, and the finished granules have high density.

6. Wide application: It can be used for particle processing of a variety of materials, such as cat litter, snow melting agent, desiccant, laundry beads, etc.

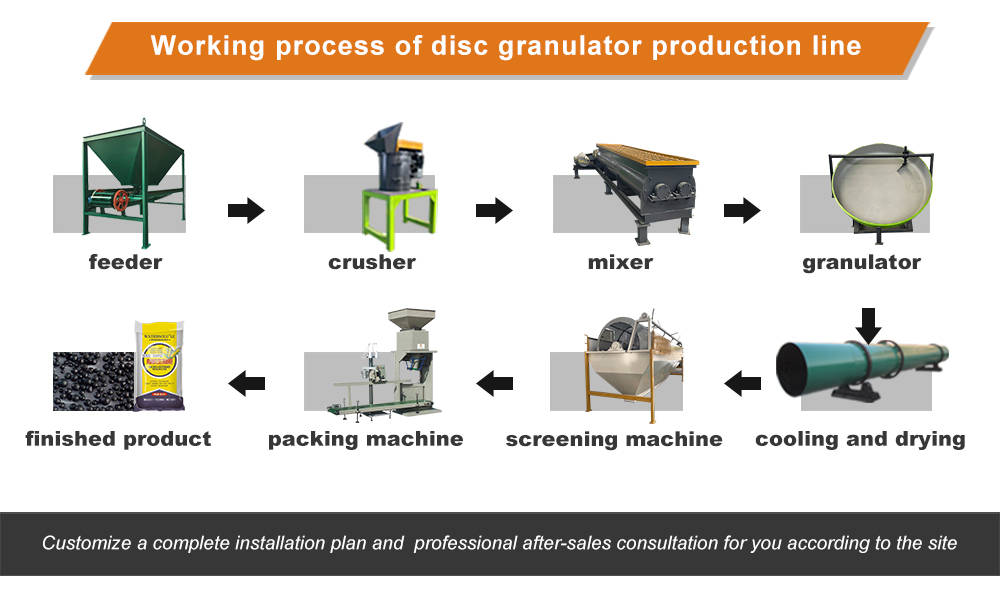

Working Process of Disc Granulating Organic Inorganic Fertilizer Production Line

The manufacturing process of the disc fertilizer granulation production line generally includes the following steps:

1. Batching equipment: It can batch different types of raw materials, including organic matter, inorganic matter and auxiliary substances.

2. Crushing and mixing: crush some lump materials and mix them thoroughly.

3. Disc granulation: The material is continuously inlaid and grown through the rolling of the disc, becoming spherical particles with consistent particle size and high density.

4. Drying and cooling: dry the finished particles to increase their hardness and facilitate subsequent transportation and storage.

5. Screening: The material is classified into particle sizes through a screening machine, and particles that do not meet the requirements are crushed and then granulated.

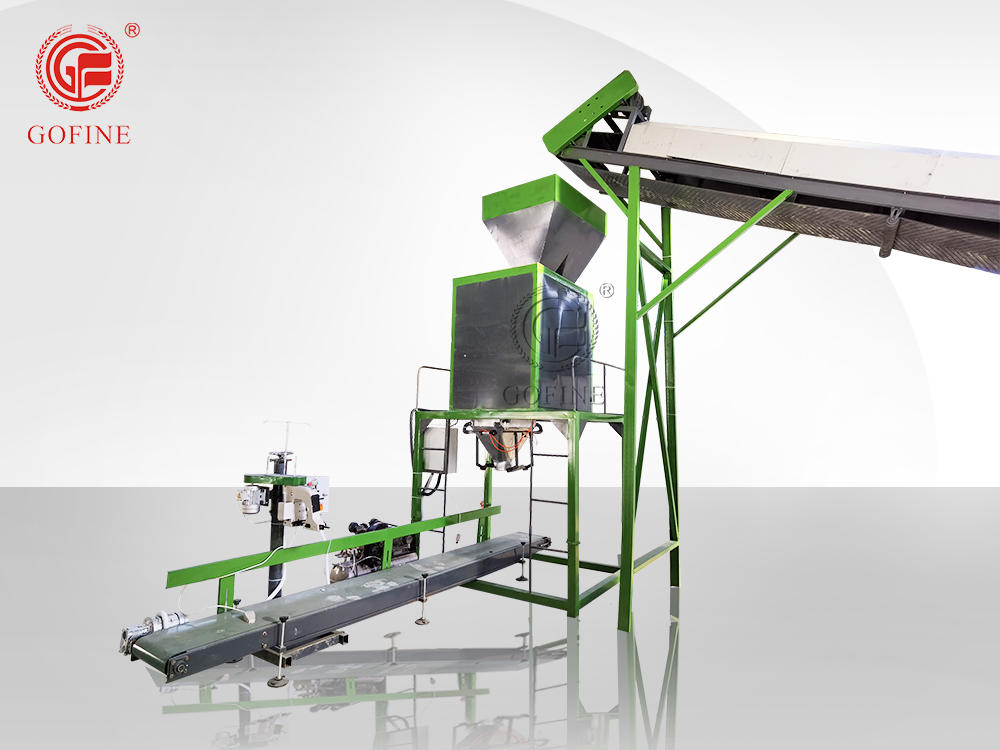

6. Packaging: The processed particles are automatically weighed and packaged, and then stored or sold directly.

Technical Parameter of Disc Granulating Organic Inorganic Fertilizer Production Line

| No | Production equipment | Process | Power | Features |

| 1 | Feeding system | transport material | 1-10kw | automated system |

| 2 | Crushing and stirring | make the material finer | 5.5-50kw | stir evenly, low residue rate |

| 3 | Further granulation | fertilizer granulating | 15-100kw | beautiful fertilizer particles |

| 4 | Dryer and cooler | keep granules moisture | 15-120kw | particle hardness |

| 5 | Sifting and packaging scale | final packing | 1-30kw | finished product |

Product Details of Disc Granulating Organic Inorganic Fertilizer Production Line