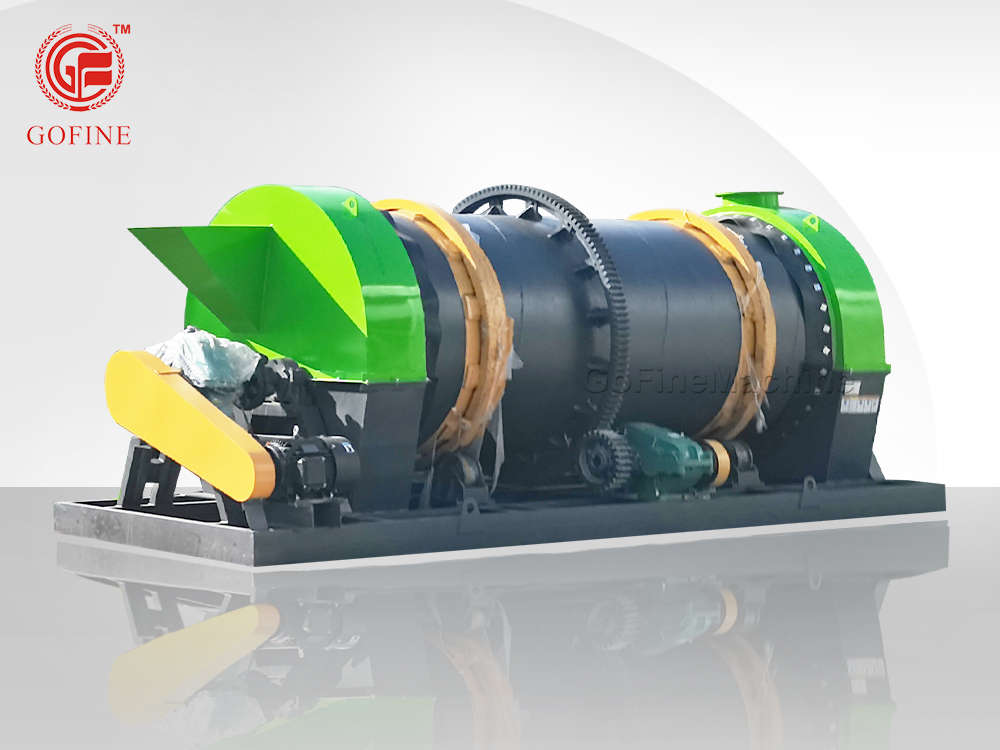

Double Roller Granulator Fertilizer Production Line

- Information

Introduction of Double Roller Granulator Fertilizer Production Line

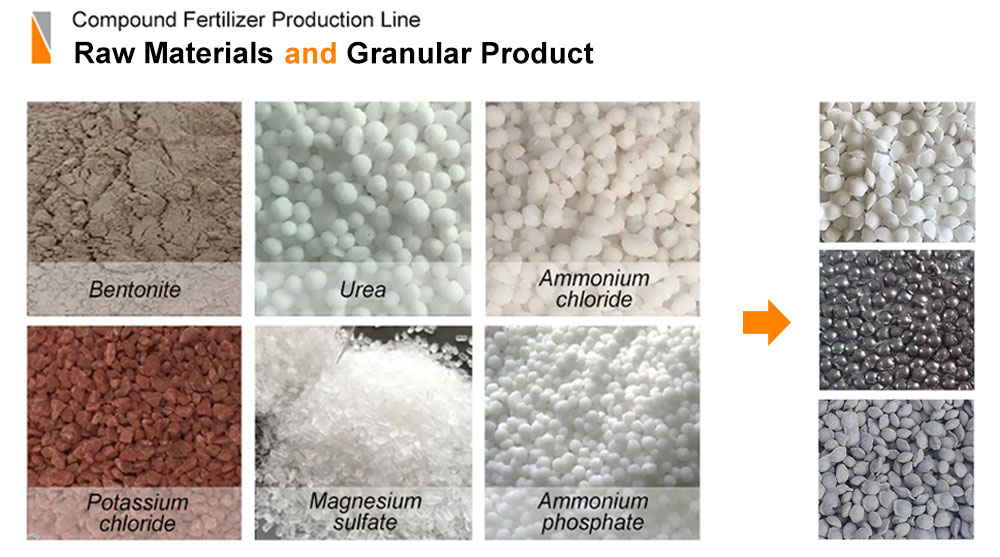

The extrusion granulation production line adopts dry granulation method and is widely used in the production of compound fertilizer granules. Through extrusion granulation, oblate granular fertilizers can be formed in one go. The conventional size is 1-6mm, and customized sizes are supported. The double-roller extrusion granulator production line has the characteristics of environmental protection, energy saving and high efficiency. The residual rate of raw materials is low, the finished granules are uniform, and the nutrients are as high as 100%. The entire production line is equipped with an automated control system, which is easy to operate, reduces manpower and improves production efficiency. Meet the needs of large-scale production and enterprise production.

Feature of Double Roller Granulator Fertilizer Production Line

1. High production capacity: using dry granulation method and one-time extrusion molding, continuous production is possible.

2. Low energy consumption: There is no need to dry after dry granulation, which reduces the energy consumption for drying and cooling of fertilizer particles.

3. Uniform particles: The materials are extruded into granules through pairs of rollers, and the finished particles have regular shapes and uniform sizes.

4. High flexibility: By adjusting the rollers, the size and hardness of the particles can be changed, and customized molds can be supported.

5. No additives required: It can be granulated without any additives, the residue rate is low, and the nutritional content is as high as 100%.

6. Automation: Realize automated production, and the production process can be automatically monitored and adjusted. Improved production efficiency and quality stability.

7. Customization: It can be designed according to customer needs to meet the output requirements of different customers.

Working Process of Double Roller Granulator Fertilizer Production Line

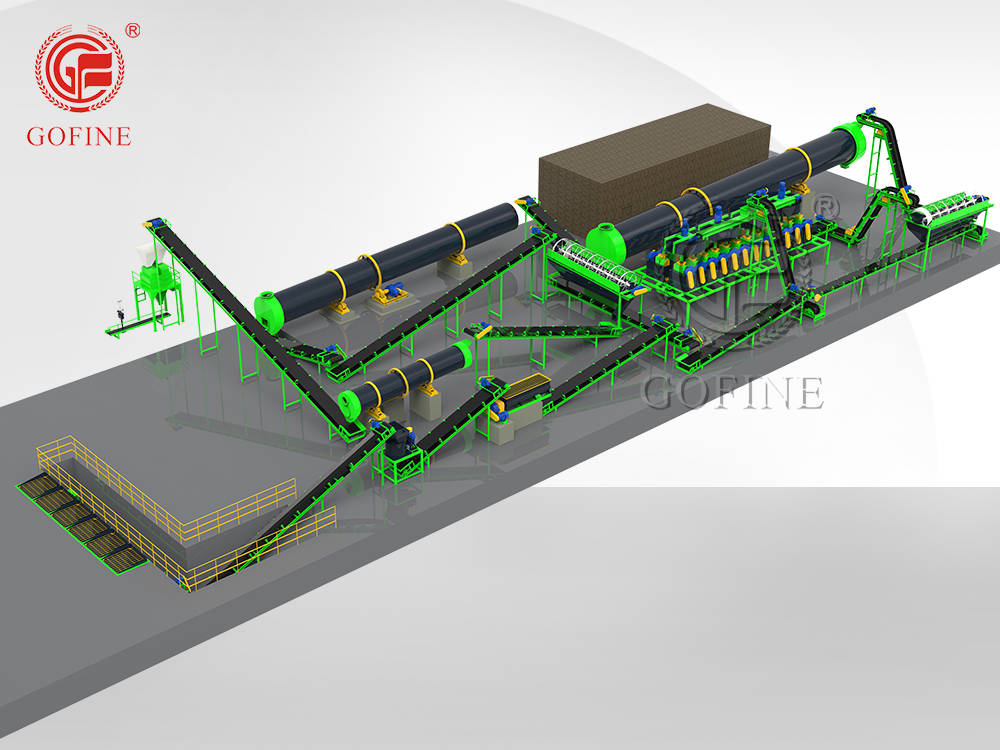

The working process of the extrusion granulation production line generally includes the following steps:

1. Batching system: Mix different raw materials in specific proportions and send them to the next production process.

2. Crusher: quickly crush materials to the ideal particle size.

3. Mixer: fully stir and mix the materials to achieve uniformity.

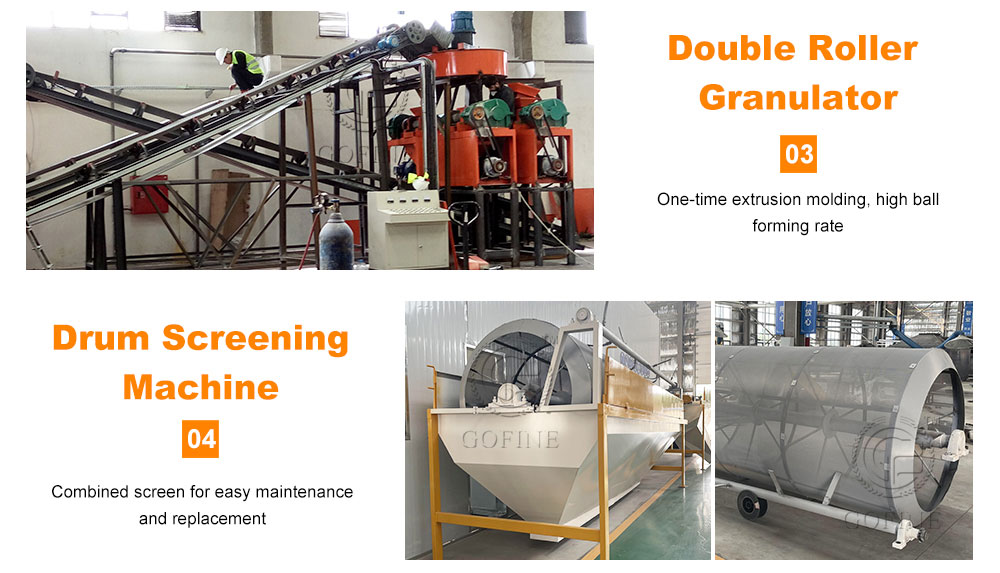

4. Extrusion granulator: Process powdery materials into granules through extrusion granulation.

5. Screening machine: Classifies the finished granules, and re-granulates those that do not meet the requirements.

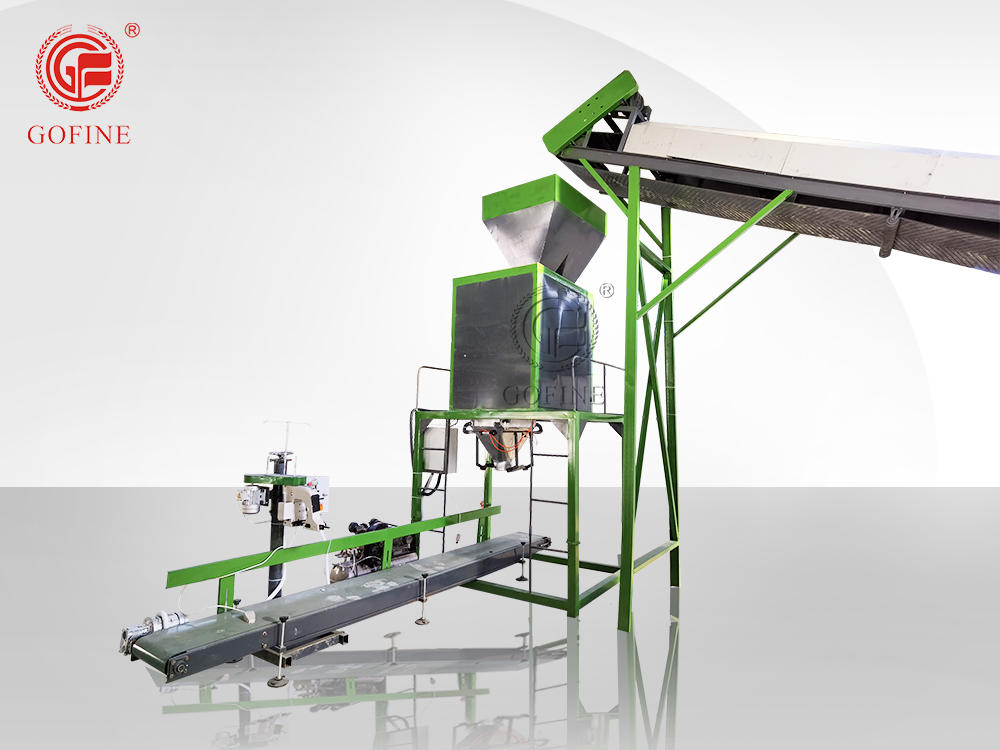

6. Packaging machine: Pack the finished granules into bags to facilitate subsequent storage and transportation.

Technical Parameter of Double Roller Granulator Fertilizer Production Line

| Item | Capacity t/h | Size m2 | Delivery time |

NPK fertilizer production line ---------- Double roller granulating plant | 1-2 | 20-40 | 15 working days |

| 5-8 | 50-100 | 20 working days | |

| 10-15 | 120-200 | 25 workig days |

Product Details of Double Roller Granulator Fertilizer Production Line