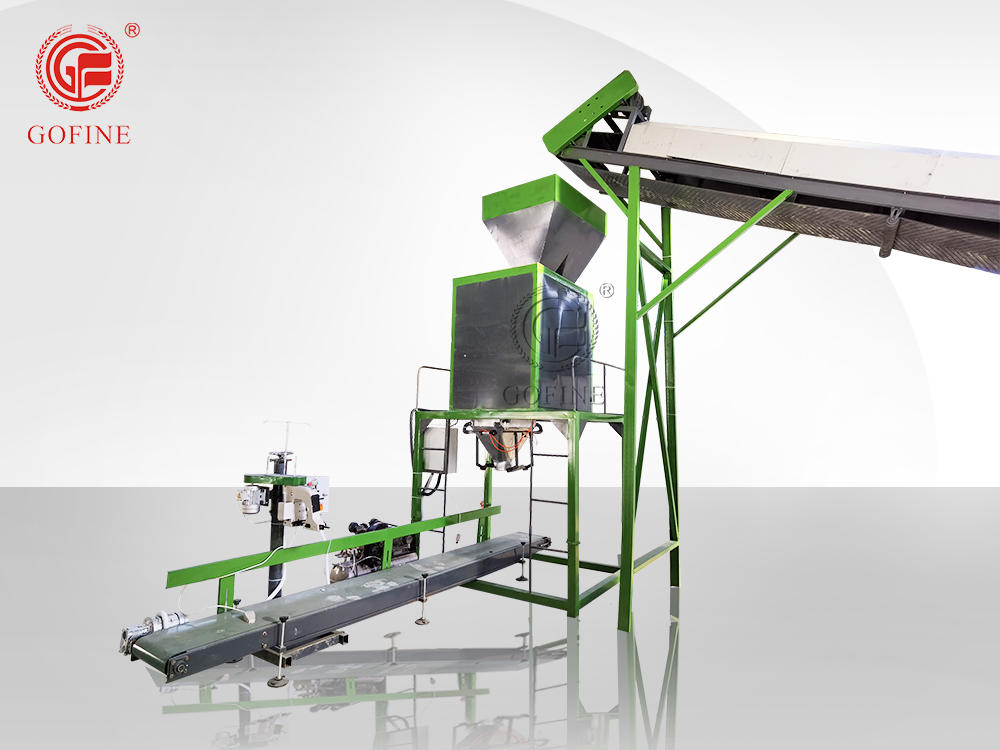

Stainless steel BB fertilizer mixer and blending equipment

- Information

Product Overview

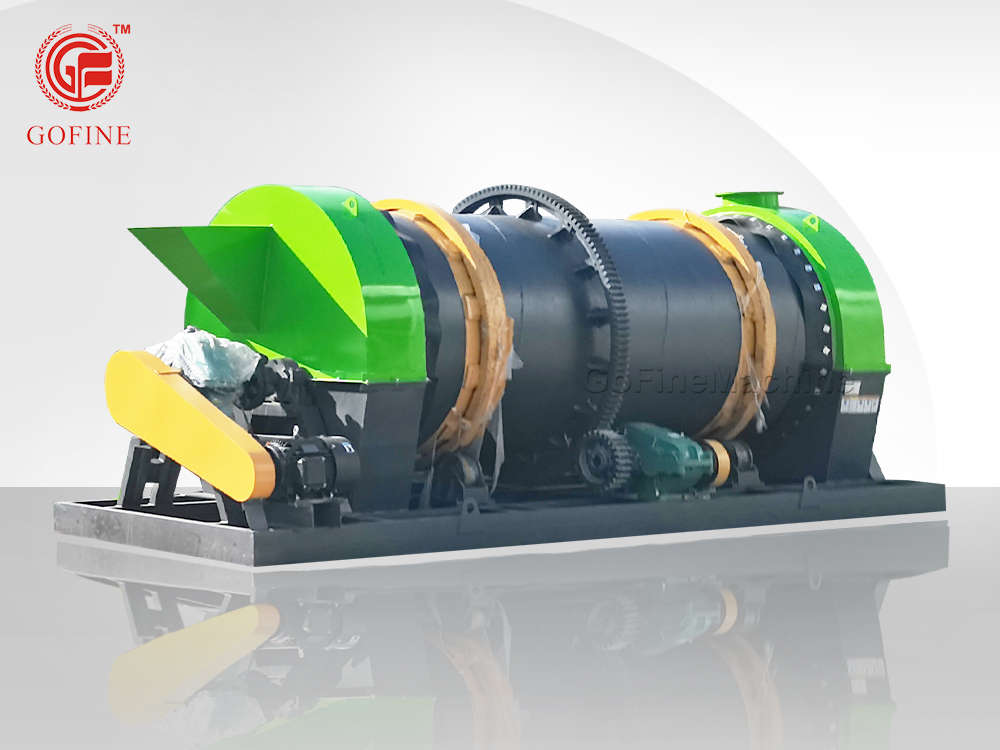

We are proud to unveil the stainless steel BB fertilizer mixer, a revolutionary advancement in stainless steel mixing technology designed specifically for the modern Bulk Blend (BB) fertilizer industry. This isn't just another ribbon blender; it's an integrated mixing system engineered for unparalleled efficiency and gentle product handling. Crafted from high-grade 304 stainless steel, its core innovation lies in the unique Triangular Spiral Agitator that combines internal feeding with external discharge, ensuring a perfectly homogeneous blend without damaging a single granule. The Gofine Machine Fusion is the definitive solution for producers who demand precision, purity, and particle integrity in every batch.

Key Features & Innovations

Integrated Loading & Mixing System: The stainless steel BB fertilizer mixer features a built-in feeding mechanism. Its unique central shaft and spiral design actively draw material in from the inlet, streamlining the process from raw material intake to final blend, reducing reliance on external equipment.

Patented Triangular Spiral Agitator: Moving beyond standard ribbons, our proprietary triangular spiral structure creates a highly efficient, three-dimensional mixing action. This design generates a powerful vortex that ensures every particle is involved in the blend.

Ultra-Gentle on Particles: The optimized geometry and rotational speed of the spiral ensure a fluidizing, rolling mix. This gentle handling is critical for preventing granule breakage, preserving the shape and size of both delicate powders and robust granules, resulting in a superior, dust-free final product.

Full 304 Stainless Steel Construction: Provides complete corrosion resistance against abrasive and chemically active fertilizers. This guarantees product purity—no rust contamination—and ensures a long operational life with minimal maintenance.

Quick Discharge & Easy Cleanability: The smooth, polished interior and strategic discharge valve placement allow for complete and rapid emptying of the batch. The simple, accessible design enables fast cleaning and changeover between different product recipes.

Applications

The stainless steel BB fertilizer mixer is exceptionally versatile, ideal for:

High-Quality BB Fertilizer Production: Perfect for uniformly blending NPK, urea, potash, DAP, and micronutrients without segregation.

Premium Powder & Granule Blending: Excellently suited for mixing powdered additives with granular base materials.

Agricultural & Horticultural Inputs: Creating consistent custom soil mixes, seed coatings, and substrate blends.

Food & Chemical Processing: Any application requiring a gentle, yet thorough, mix of dry particulates where hygiene and product integrity are paramount.

Work Process

Step 1: Active Infeed. The process begins as materials are introduced into the hopper. The rotating triangular spiral agitator actively engages, using its internal infeed action to pull material into the mixing chamber, facilitating a rapid and efficient loading phase.

Step 2: 3D Fusion Blending. Once loaded, the mixer continues its cycle. The unique spiral creates a multi-directional flow. Material is continuously drawn from the core and pushed to the periphery, folding back upon itself. This creates a highly turbulent yet gentle "figure-eight" pattern that envelops all particles for a perfect, non-segregating blend.

Step 3: Gentle Particle Preservation. Throughout the blending cycle, the rolling and fluidizing motion ensures that particles are never subjected to high-impact shear forces. This is the key to achieving zero breakage, maintaining the perfect granule structure of your raw materials.

Step 4: Complete External Discharge. Upon completion of the blend cycle, the discharge valve opens. The continued rotation of the spiral agitator uses its external discharge action to positively and swiftly evacuate the entire batch from the bottom outlet, leaving no residue behind and preparing the system for the next batch.

Experience the gentle, efficient blending. Contact us today to learn how the stainless steel BB fertilizer mixer can enhance your product quality and operational productivity.