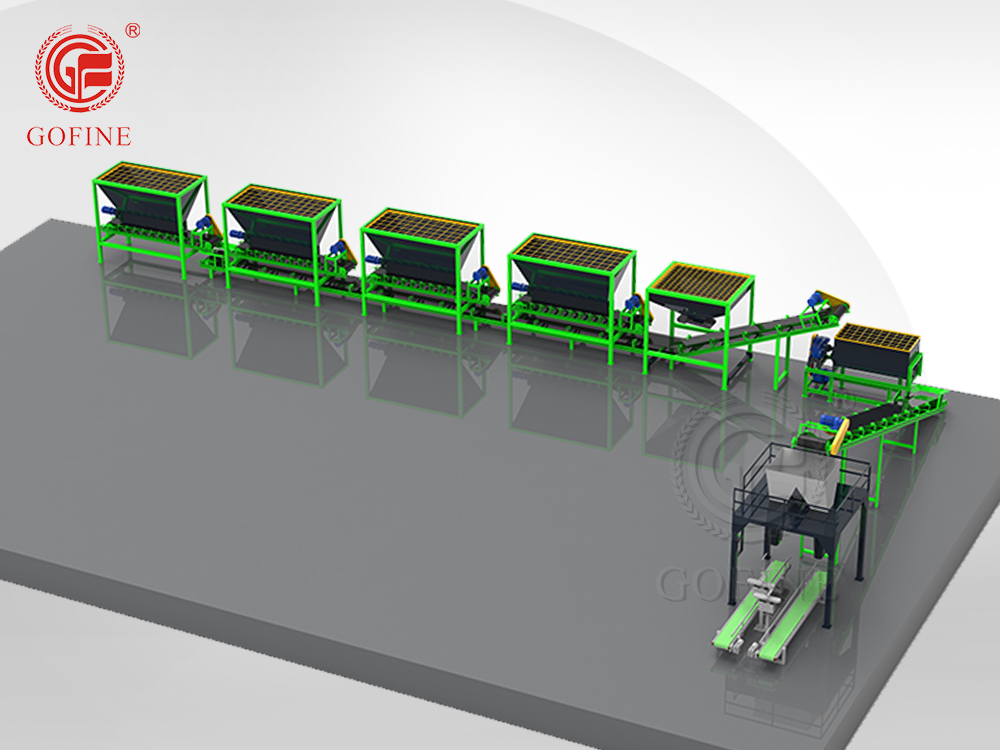

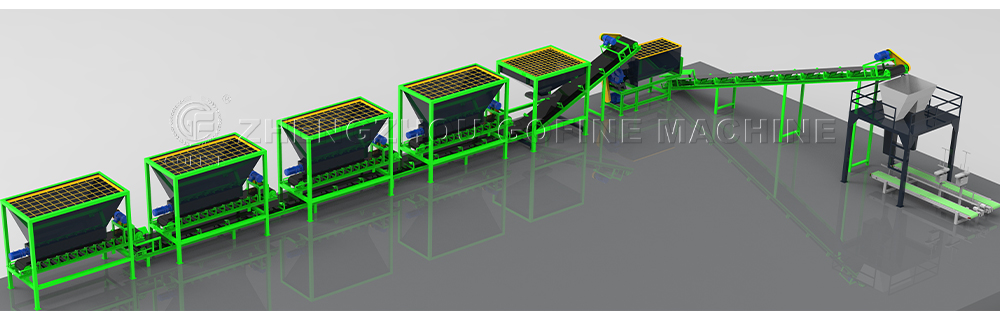

Nursery Organic Composting Fertilizer Seedling Potting Mix Production Line

- Information

Overview

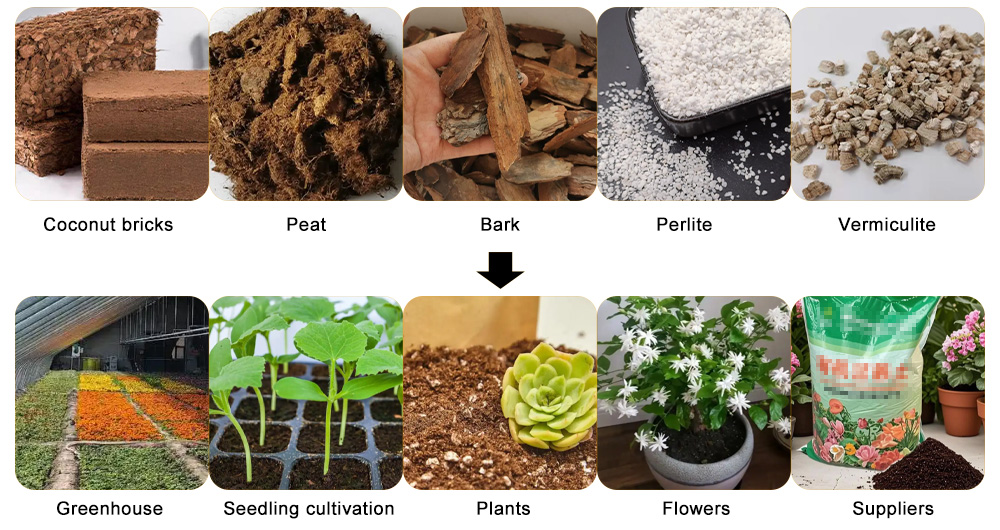

The Gofine Machine seedling substrate production line is a technologically advanced system designed to produce high-quality, homogeneous, and well-aerated seedling substrates, crucial for successful seedling cultivation. This integrated line goes beyond the capabilities of a standard potting mix, effectively addressing the unique challenges of blending lightweight, fine-particle components such as coconut fiber, perlite, and vermiculite. It is ideal for commercial nurseries, greenhouses, and horticultural businesses that demand extremely high levels of uniformity and precision in mixing. This line ensures that every batch of indoor seedling substrate provides the perfect foundation for root development and healthy plant growth.

Key Features

Our production line is distinguished by its precision, reliability, and innovative handling of delicate materials.

Specialized Coir Processing: The line begins with a powerful coco peat breaker, efficiently transforming compacted coir bricks into a fine, consistent fiber, ready for optimal blending.

Anti-Bridging & Consistent Feeding: A unique combination of a volumetric feeder and a vibrating feeder ensures a continuous, non-stop flow of all raw materials. This critical feature prevents blockages commonly caused by moist coir or other sticky additives, guaranteeing uninterrupted production.

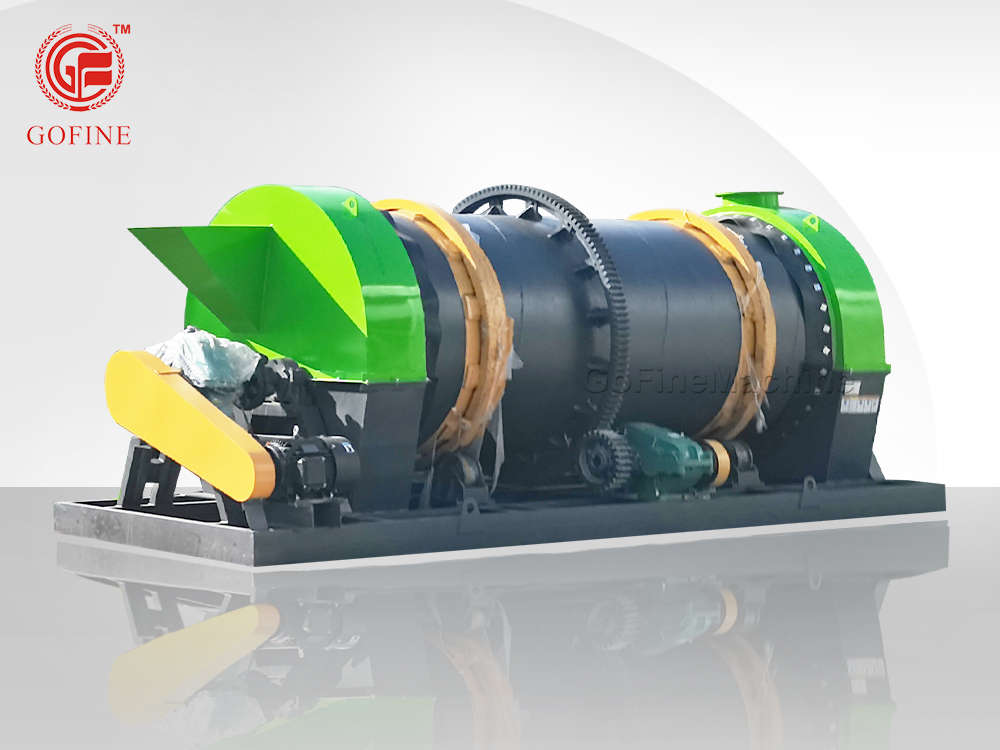

Thorough and Gentle Mixing: At the heart of the system is our Industrial Soil Mixer, configured here as a dual-axis paddle Soil Blender. It achieves a homogenous blend without damaging the delicate structure of perlite or vermiculite, preserving the aeration vital for seedling roots.

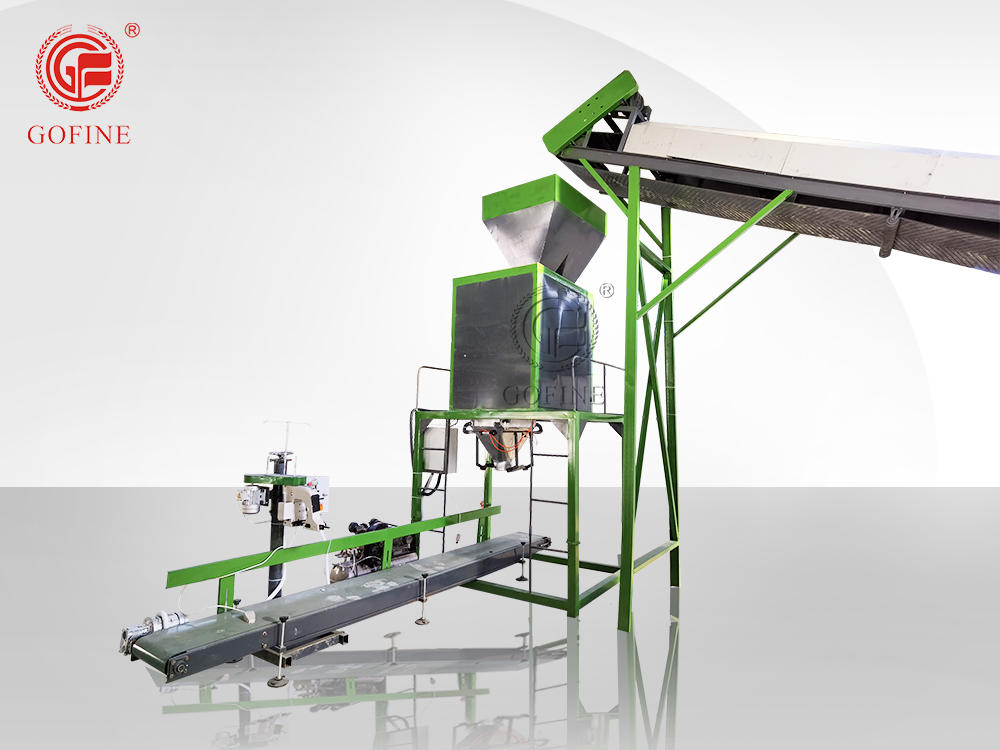

Revolutionary Volumetric Weighing & Packaging: Unlike conventional systems that struggle with lightweight materials, our advanced volumetric packaging machine provides unparalleled accuracy. This method is far more precise for weighing lightweight components like perlite, which are critical for drainage and aeration in seedling mixes, ensuring every bag has the correct composition.

Applications

This specialized line is ideal for producing growing media for:

Commercial Vegetable and Flower Seedling Production: Creating the uniform, disease-free mix required for high-density plug trays and cell packs.

Greenhouse Propagation: Supplying a consistent Greenhouse Dirt Mixer blend for cuttings and seed starting.

Horticultural Nurseries: Producing specialized mixes for trees, shrubs, and ornamental plants at the most vulnerable early growth stage.

Wholesale Soil Manufacturers: Offering a superior, precision-blended seedling mix product for the retail market.

Production Process

The production process is a seamless, automated sequence designed for precision from raw material to packaged product.

Stage 1: Coir Size Reduction

Compacted coir bricks are fed into the crusher, where they are broken down into a loose, uniform fiber. This is the essential first step to ensure mix consistency.

Stage 2: Precision Metering and Feeding

The processed coir, along with other components like peat and compost, is fed via the Volumetric Feeder.

A Vibrating Feeder actively prevents bridging and clogging, ensuring a smooth flow of materials into the mixing stage. This is a critical improvement over standard Soil Blending Equipment.

Stage 3: Homogenization

All materials are conveyed into the Soil Mixer Machine—a robust Dual-Shaft Paddle Mixer. This Soil Batch Mixer thoroughly integrates coir, compost, perlite, vermiculite, and nutrients into a perfectly uniform Soil Mixture Machine output, ideal for delicate seedling roots.

Stage 4: Accurate Packaging

The finished blend is transported to the volumetric weighing and packaging machine. This innovative system measures the mix by volume, guaranteeing that the final bagged product contains the precise ratio of lightweight ingredients, a feat unattainable with standard weight-based baggers.

Why Choose Our Seedling Mix Line?

This is more than just a Potting Soil Mixer for Sale; it is a comprehensive Soil Mixing Plant solution built for perfection. We have engineered this line to solve the specific pain points of seedling mix production, particularly the handling of coir and the precise incorporation of lightweight aggregates. By choosing our equipment, you invest in a system that guarantees product quality, maximizes operational efficiency, and minimizes waste, giving you a significant competitive edge in the market of professional growing media.

For operations requiring smaller-scale solutions, we also offer standalone Soil Mixer models that incorporate these precision-mixing principles.

Nutrient potting soil production line customer site