Complete SCU Fertilizer Urea Coating Production Line Solution

- Information

Product Introduction

Controlled-release and slow-release fertilizers are new types of fertilizers that utilize specialized processes (including but not limited to coating and chemical synthesis) to achieve intelligent, controlled nutrient release. Urea coating, a core process, forms one or more layers of coating on the surface of urea granules through physical or chemical methods to control the nitrogen release rate, improve fertilizer utilization, and reduce environmental pollution.

Urea coating technologies can be categorized into three main types based on the coating material:

Inorganic urea coatings (e.g., sulfur and mineral coatings)

Organic urea coatings (e.g., polymer and resin coatings)

Complex urea coatings (inorganic + organic mixed coatings)

Each technology offers unique advantages and is suitable for different crops, soils, and climate conditions.

Gofine Machine is a leading fertilizer equipment manufacturer in China, specializing in the research, development, and manufacturing of controlled-release fertilizers, slow-release fertilizers, and urea coating production lines. We offer comprehensive solutions, from single-unit equipment to complete turnkey plants.

Core Advantages:

Independent R&D - We hold multiple patents covering coating, controlled-release, and intelligent control.

Customized Service - We can adjust equipment parameters to suit different coating processes (sulfur, polymer, composite film, etc.) according to customer needs.

Cost-Effective - Compared to imported equipment, we offer 30%-50% lower costs and easier maintenance.

Intelligent Control - Integrated PLC system enables real-time monitoring of production data.

Introduction to the Rotary Drum Urea Coating Line

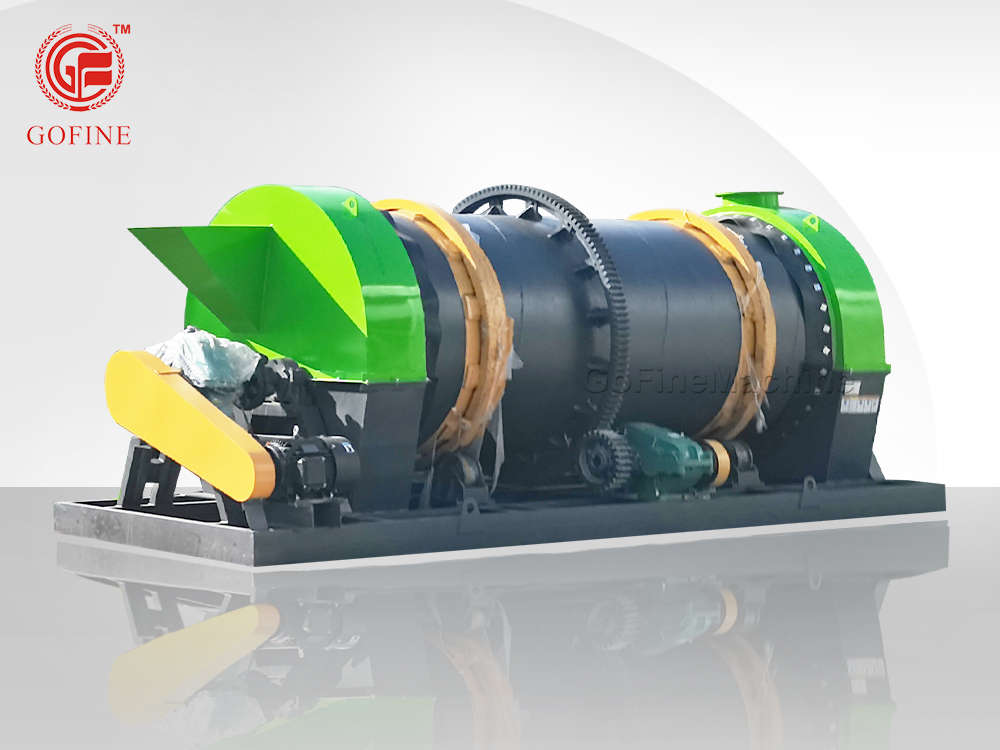

This rotary drum urea coating line is specialized equipment developed by our company for the production of sulfur-coated urea (SCU) and composite-coated urea. Utilizing proven rotary drum coating technology, it offers uniform coating, stable operation, and easy operation.

Production Line Components

1. Urea Pretreatment System

Vibrating Screener: Removes urea powder and impurities

Preheater: Raises the temperature of urea granules to 50-60°C

2. Core Coating Equipment

Drum Coating Machine (Patented Design):

Drum diameter adjustable from 1.5-3m

Tilt angle adjustable from 5-15°

VFD-controlled speed (5-25 rpm)

3. Coating Material System

Precision Spraying System: Airless spraying for uniform atomization

4. Post-Processing System

Pellet Cooler

Vibrating Screener

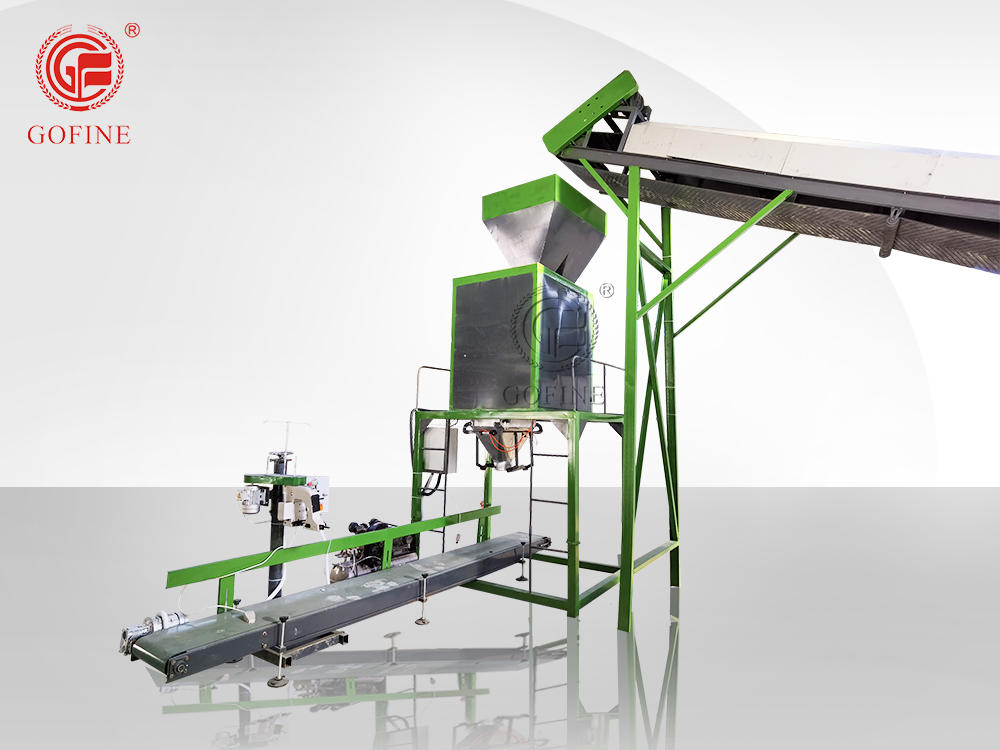

Automatic Packaging Machine

Technical Parameters

Project Parameters

Production Capacity 2-15 tons/hour

Coating Uniformity ≥93%

Coating Thickness 20-100μm Adjustable

Power Consumption ≤25kW·h/ton

Operators 2-3 people/shift

Product Advantages

Excellent coating quality: Patented drum structure ensures uniform coating

Low energy consumption: 15-20% less energy than traditional equipment

Adaptable: Capable of processing urea particles from 1 to 4 mm in size

Easy maintenance: Modular design allows for easy access

Urea coating technology offers inorganic, organic, and composite coating solutions to meet the needs of diverse agricultural scenarios. Growers can select the most suitable controlled-release fertilizer product based on crop type, soil conditions, and budget to achieve the goals of reduced weight, increased efficiency, and sustainable farming.

For specific technical specifications or customized solutions, please feel free to contact me!