Bulk Blending Plant BB Fertilizer Production Line Manufacturer

- Information

Overview

The Gofine Bulk Blend (BB) Fertilizer Production Line is a complete, modular, and automated system engineered for the precise, high-volume production of customized blended fertilizers. Also known as a Dry Fertilizer Blending Plant, this line enables producers to efficiently combine granular base materials like urea, DAP, MOP, and various micronutrients into uniform, high-quality NPK blends tailored to specific soil test results and crop requirements. We transform the complex process of fertilizer formulation into a streamlined, profitable, and quality-controlled operation, empowering you to respond swiftly to market demands with consistent, reliable products.

Key Features & Client-Centric Advantages

Formula Flexibility & Precision Batching: Utilize our automatic batching system with high-precision load cells and computerized control. This allows you to easily switch between countless NPK fertilizer formulas with pinpoint accuracy, minimizing nutrient deviation and ensuring every batch meets the specified soil testing formula standards.

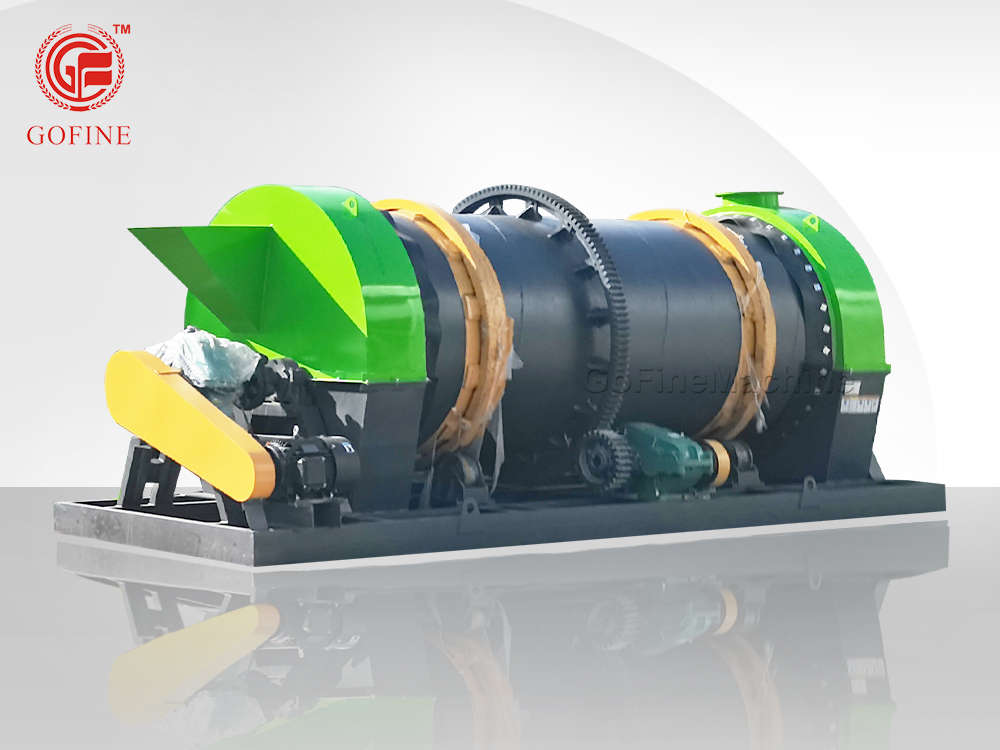

Superior Mixing Homogeneity: At the heart of the line is our high-efficiency fertilizer mixer machine (typically a dual-axis paddle mixer or rotary drum blender). It ensures a complete, gentle yet thorough blend in 3-5 minutes, guaranteeing uniform nutrient distribution in every granule and preventing segregation.

Turnkey & Scalable Design: We provide a complete compound fertilizer equipment solution—from raw material receiving and storage to blending, packaging, and automation. The modular design allows for future expansion, growing your capacity as your business grows.

Intelligent Control & Data Management: The integrated PLC control system offers recipe management, production data logging, and real-time monitoring. This brings transparency to your fertilizer production process, reduces human error, and ensures traceability for quality assurance.

Dust-Free & Efficient Handling: Enclosed conveyors (belt or bucket elevator), dust collection systems, and optimized material flow paths maintain a clean plant environment, reduce product loss, and protect operator health.

Applications

This production line is the core asset for:

Establishing or upgrading a dedicated Bulk Blend Fertilizer (BB Fertilizer) manufacturing plant.

Serving the growing demand for prescription fertilization and soil testing formula fertilizer programs in modern agriculture.

Producing a wide range of granular fertilizer blends, including NPK fertilizers, secondary nutrient blends, and specialty crop-specific formulations.

Granular Fertilizer Production for both large-scale agribusiness and regional blenders.

Work Process

The operation follows a seamless, automated sequence designed for efficiency and quality control:

Raw Material Intake & Pre-Storage: Granular base fertilizers are received and stored in separate bulk bins or silos to prevent cross-contamination.

Automated Precision Dosing: According to the selected digital recipe, the automatic batching system precisely weighs and discharges the required amount of each raw material via vibratory feeders or screw conveyors onto a collecting belt.

High-Speed Blending: The pre-weighed materials are conveyed into the fertilizer mixing equipment. The intensive mixer operates for a pre-set time, achieving a perfectly homogeneous blend.

Discharge & Conveying: The uniform blend is discharged and elevated to the next stage, often passing through a screening device to remove any oversize or dust, ensuring only on-specification product proceeds.

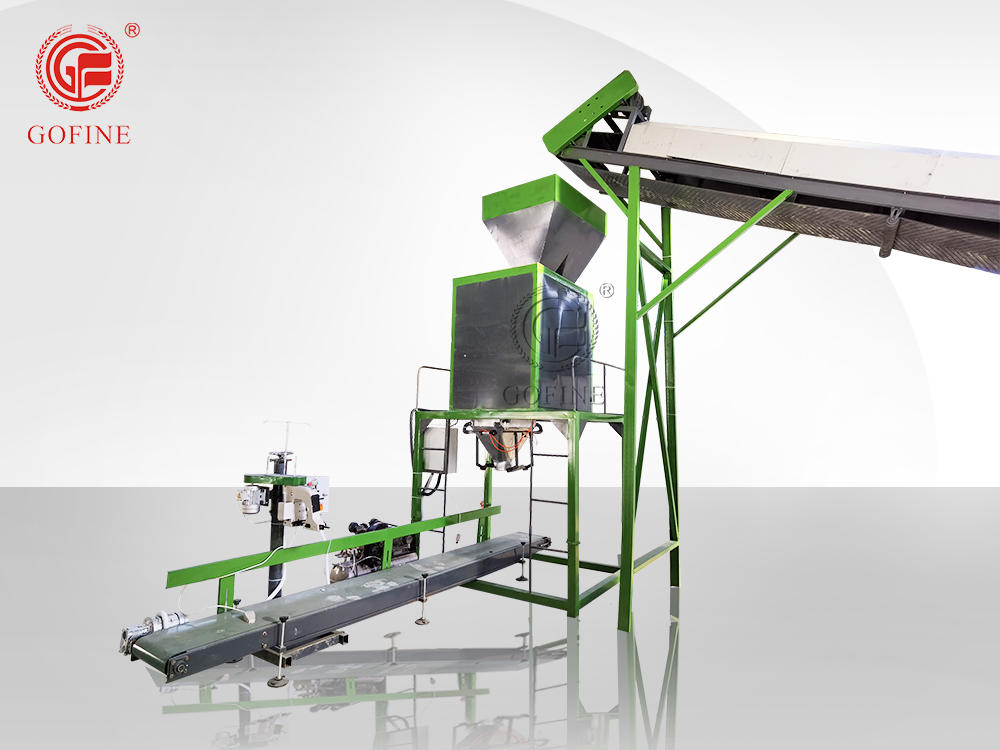

Weighing & Packaging: The finished blend is fed into an automated fertilizer packaging line, such as a weighing and bagging machine for 25kg/50kg bags or a ton bag packing machine for bulk orders.

Palletizing & Dispatch: Bagged products are automatically palletized and moved to storage, ready for shipment to distributors and farms.

Why choose the Gofine BB Fertilizer Mixer?

This production line solves your core problems:

Meeting market demand: Enabling you to profitably produce small batches of customized blended fertilizers, meeting the precise needs of different crops and regions.

Ensuring product quality and consistency: Eliminating inaccurate mixing and nutrient segregation issues, enhancing your brand reputation.

Maximizing operational efficiency: Automation reduces reliance on manual labor, increases output, and minimizes raw material waste.

Providing a clear growth path: This is a scalable, turnkey system that supports your business expansion from day one.