Rotary Drum Granulation Fertilizer Production Line

- Information

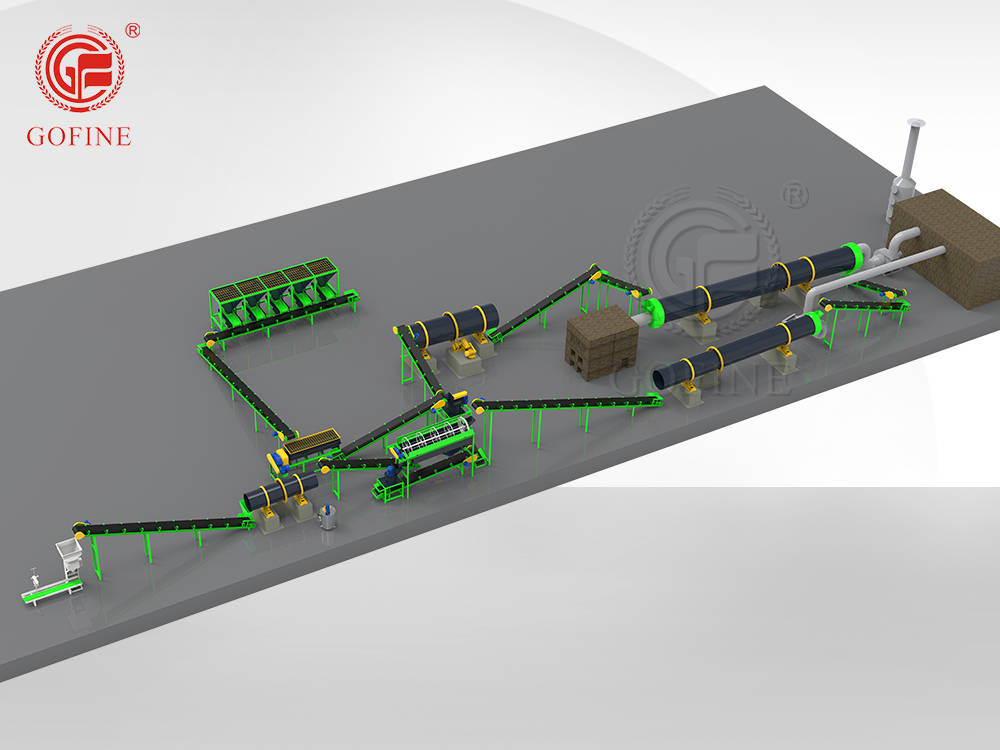

Introduction of Rotary Drum Granulation Fertilizer Production Line

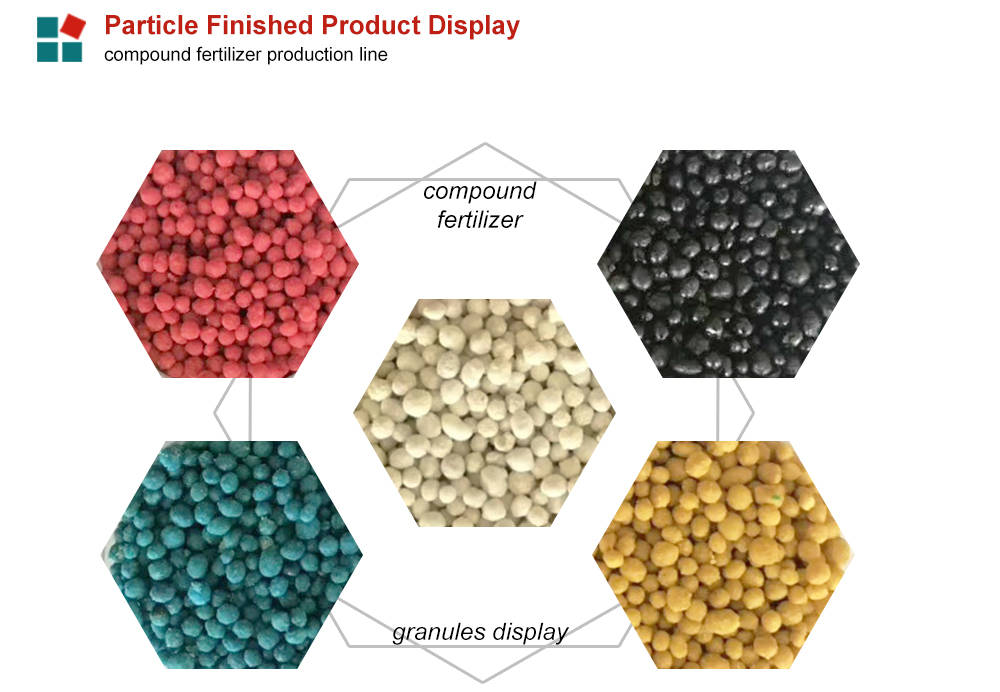

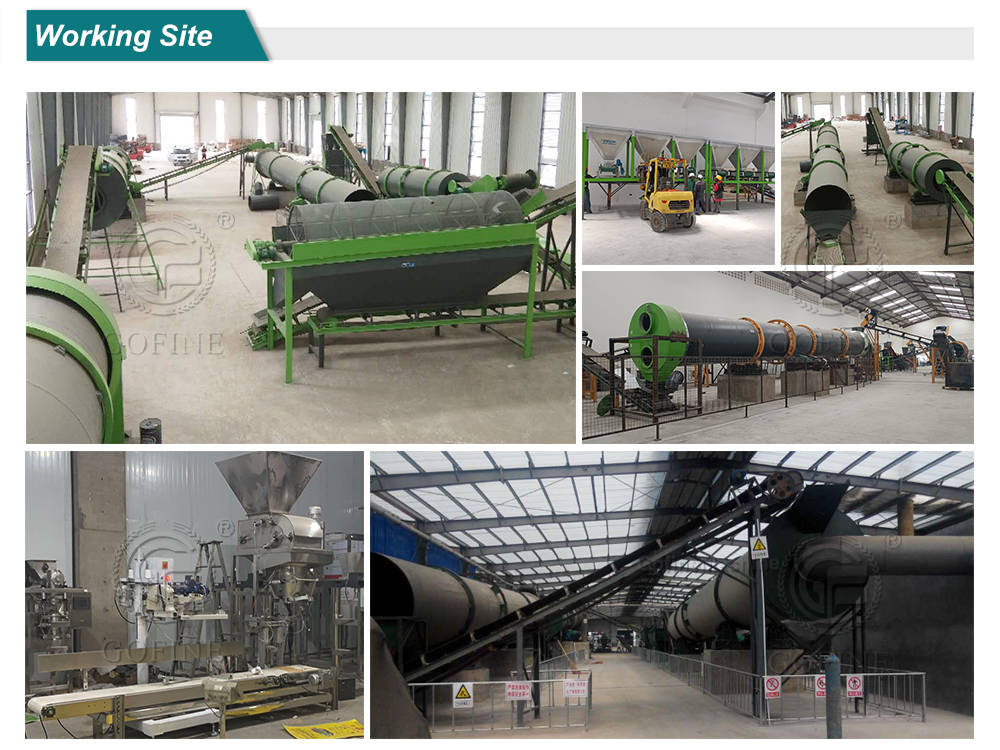

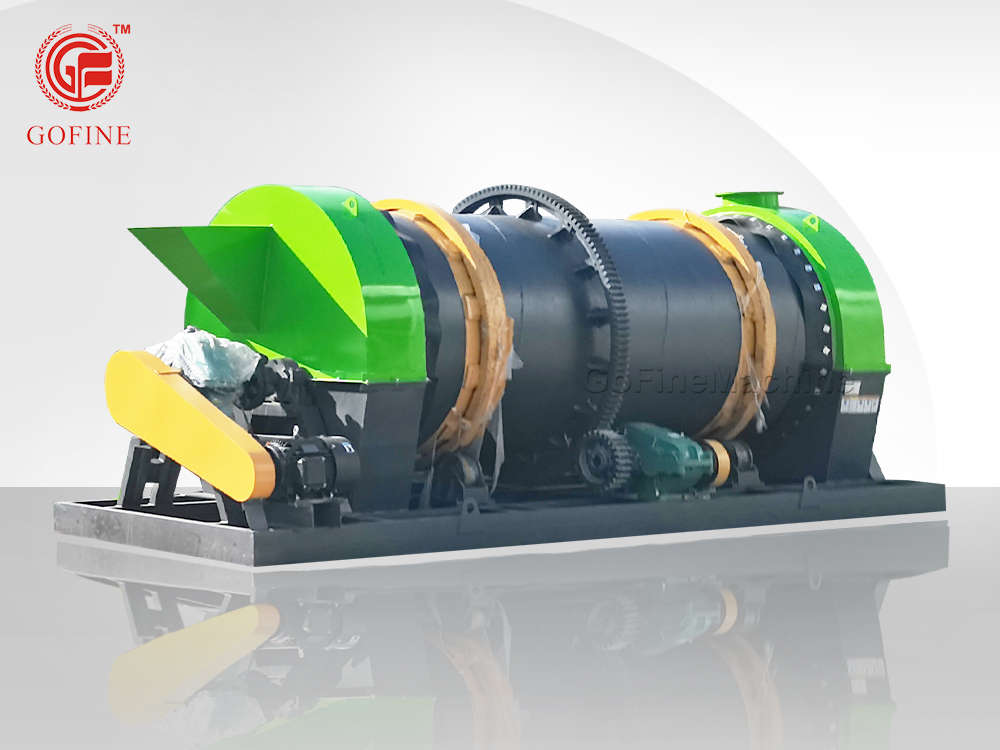

The rotary drum granulation production line is widely used in granule processing and manufacturing in agriculture, chemical industry, fruit and vegetable cultivation, fertilizer production plants and other fields. It is one of the key equipment in the compound fertilizer industry and is suitable for cold and hot granulation, as well as the large-scale production of high, medium and low concentration compound fertilizers. The raw materials can be automatically mixed, crushed, stirred, granulated, dried, screened and other processes to finally produce compound fertilizer particles with uniform particle size and strong hardness. The drum granulator adopts wet granulation method and has a high balling rate. The lining is made of special material and is corrosion-resistant. Meet the needs of different outputs and achieve automated continuous production.

Feature of Rotary Drum Granulation Fertilizer Production Line

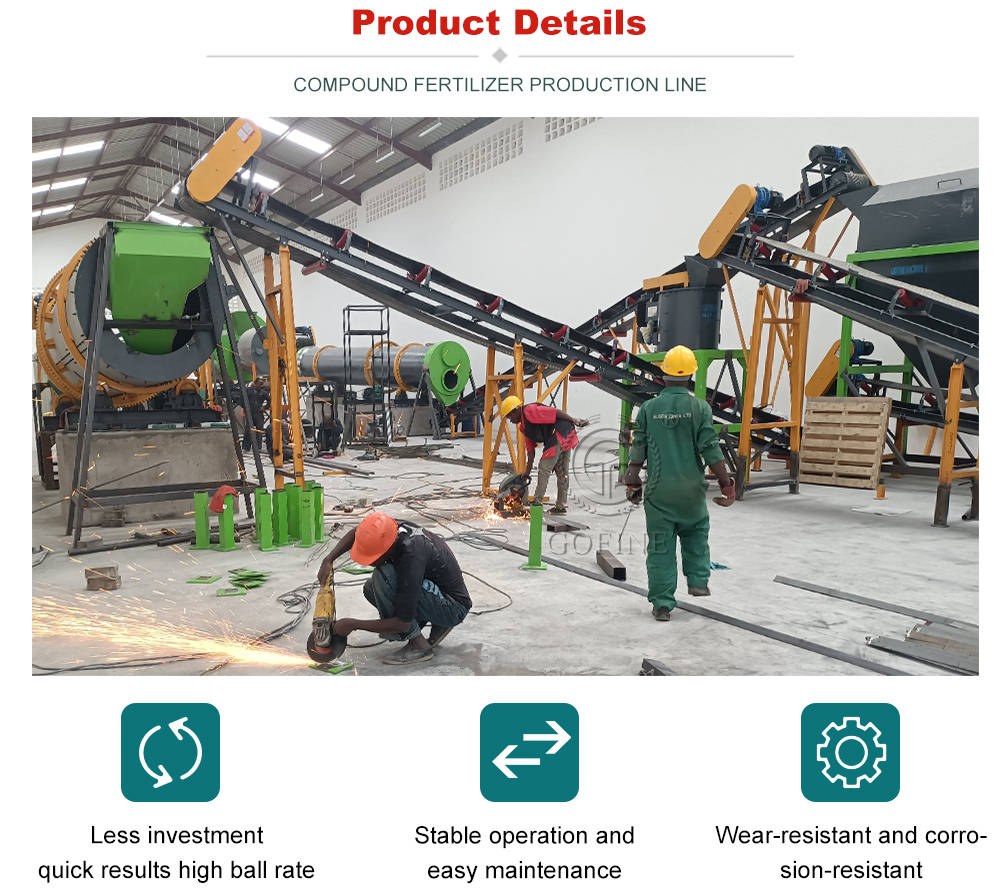

1. Wet granulation: The granultor have high density and regular shape without any additives.

2. High degree of automation: using an automated control system, the finished particles are of high quality.

3. High production efficiency: realize continuous production, reduce manual operations and improve production efficiency.

4. Corrosion resistance: The lining is made of special material, which is corrosion-resistant and wear-resistant, and is easy to clean later.

5. Low energy consumption: Adopt energy-saving design to reduce energy consumption. Hot air circulates during drying to improve energy utilization.

6. Strong environmental protection: it can effectively handle organic waste and process it into organic fertilizer particles.

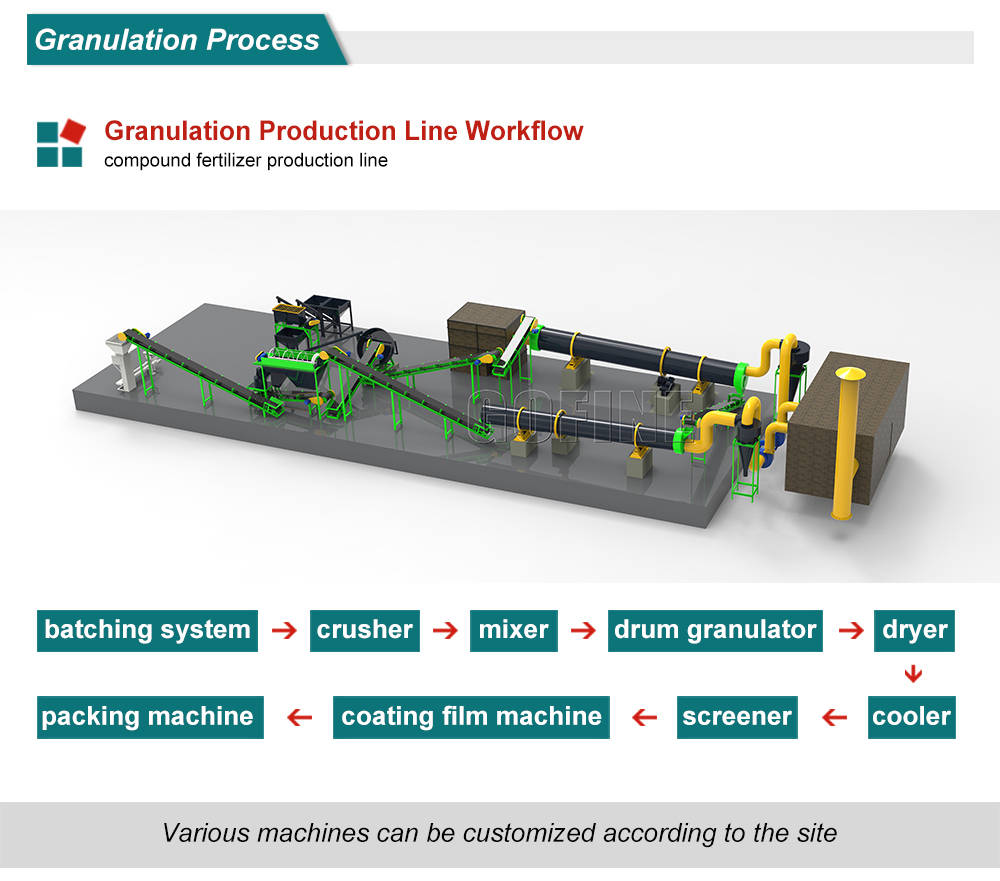

Working Process of Rotary Drum Granulation Fertilizer Production Line

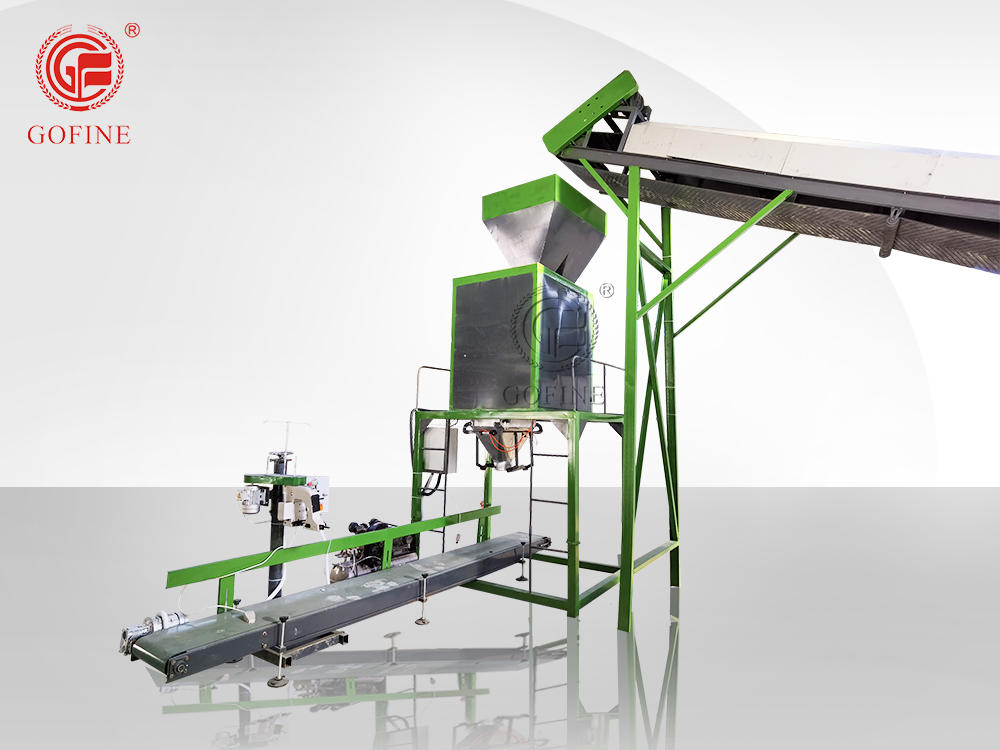

The drum granulation production line is an efficient fertilizer granule processing line that can process powdery or granular raw materials into ideal granular products. The raw materials are first sent to the feed port of the drum granulation production line through the feeding device. The raw materials are thoroughly mixed through the crusher and mixer and sent to the drum granulator. The raw materials rub against the surface of the drum in the drum, and are affected by centrifugal force. The molecules continue to roll and grow, forming spherical particles with a tight structure. The processed particles undergo a drying and cooling process to improve the hardness of the particles, which facilitates subsequent storage and transportation. The screening machine screens and grades the finished granules to improve the quality of the granules. Unsatisfactory particles are crushed and re-granulated through the belt conveyor. Finally transported to the automatic weighing and packaging machine for packaging.

Technical Parameter of Rotary Drum Granulation Fertilizer Production Line

| Item | Capacity t/h | Size m2 | Delivery time |

NPK Fertilizer Production Line --- Rotary Drum Granulating Plant | 3-5 | 30-50 | 15 working days |

| 8-10 | 50-100 | 20 working days | |

| 10-15 | 120-200 | 25 working days |

Product Details of Rotary Drum Granulation Fertilizer Production Line